- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄383983 > UPD75236 (NEC Corp.) 4-BIT SINGLE-CHIP MICROCOMPUTER PDF資料下載

參數(shù)資料

| 型號(hào): | UPD75236 |

| 廠商: | NEC Corp. |

| 英文描述: | 4-BIT SINGLE-CHIP MICROCOMPUTER |

| 中文描述: | 4位單片機(jī) |

| 文件頁數(shù): | 185/190頁 |

| 文件大小: | 1220K |

| 代理商: | UPD75236 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁第85頁第86頁第87頁第88頁第89頁第90頁第91頁第92頁第93頁第94頁第95頁第96頁第97頁第98頁第99頁第100頁第101頁第102頁第103頁第104頁第105頁第106頁第107頁第108頁第109頁第110頁第111頁第112頁第113頁第114頁第115頁第116頁第117頁第118頁第119頁第120頁第121頁第122頁第123頁第124頁第125頁第126頁第127頁第128頁第129頁第130頁第131頁第132頁第133頁第134頁第135頁第136頁第137頁第138頁第139頁第140頁第141頁第142頁第143頁第144頁第145頁第146頁第147頁第148頁第149頁第150頁第151頁第152頁第153頁第154頁第155頁第156頁第157頁第158頁第159頁第160頁第161頁第162頁第163頁第164頁第165頁第166頁第167頁第168頁第169頁第170頁第171頁第172頁第173頁第174頁第175頁第176頁第177頁第178頁第179頁第180頁第181頁第182頁第183頁第184頁當(dāng)前第185頁第186頁第187頁第188頁第189頁第190頁

185

μ

PD75236

14.

RECOMMEDED SOLDERING CONDITIONS

The

μ

PD75236 should be soldered and mounted under the conditions recommended in the table below.

For soldering methods and conditions other than those recommended below, contact our salesman.

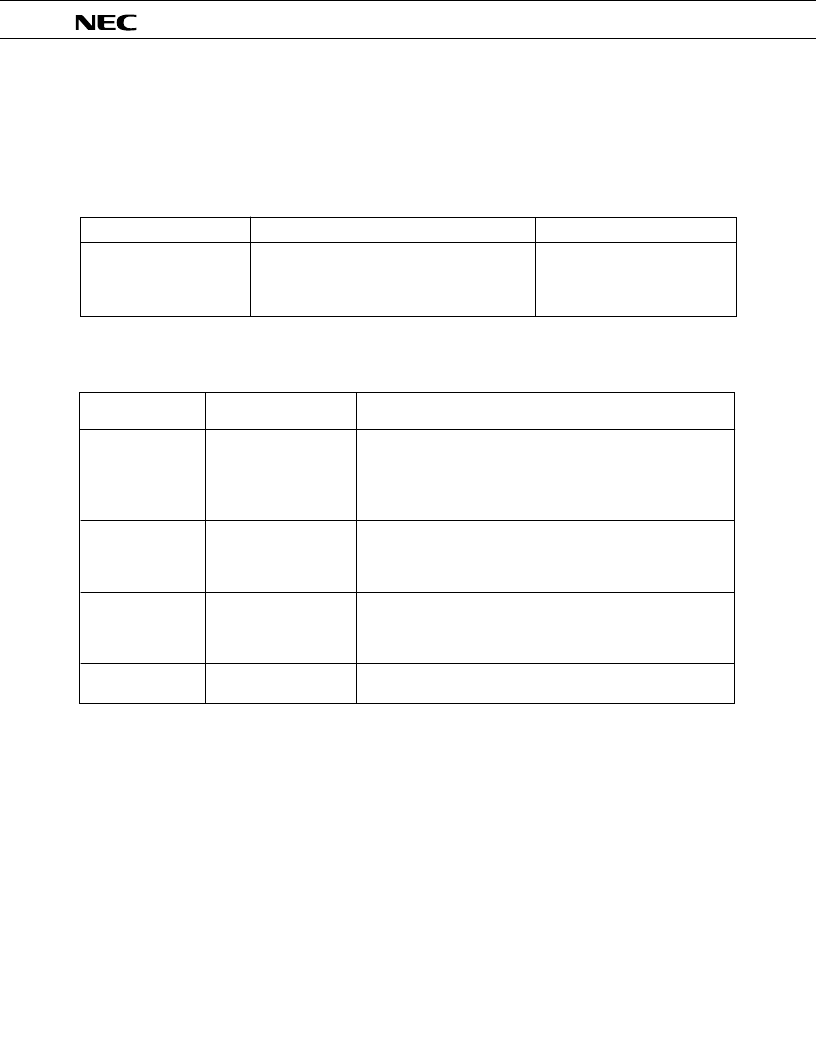

Table 14-1 List of Recommended Soldering Conditions

Table 14-2 Soldering Conditions

*

For the storage period after dry-pack decompression, storage conditions are max. 25

°

C, 65% RH.

Note

Use of more than one soldering method should be avoided (except in the case of pin part heating).

Remarks

For details of recommended soldering conditions for the surface mounting type, refer to the docu-

ment

“Semiconductor Device Mount Technology” (IEI-1207)

.

Product Name

Package

Recommended Condition Symbol

WS60-107-1

IR30-107-1

VP15-107-1

Pin part heating

μ

PD75236GJ-

×××

-5BG

94-pin plastic QFP

Recommended

Condition Symbol

Soldering Conditions

Solder bath temperature: 260

°

C or less

Duration: 10 sec. max.

Number of times: Once

Time limit: 7 days

*

(thereafter 10 hours prebaking required at 125

°

C)

Preheating temperature: 120

°

C max. (package surface temperature)

Package peak temperature: 230

°

C

Duration: 30 sec. max. (at 210

°

C or above)

Number of times: Once

Time limit: 7 days

*

(thereafter 10 hours prebaking required at 125

°

C)

Package peak temperature: 215

°

C

Duration: 40 sec. max. (at 200

°

C or above)

Number of times: Once

Time limit: 7 days

*

(thereafter 10 hours prebaking required at 125

°

C)

Pin part temperature: 300

°

C or less

Duration: 3 sec. max. (Per device side)

Soldering Method

Wave Soldering

Infrared reflow

VPS

Pin part heating

WS60-107-1

IR30-107-1

VP15-107-1

Pin part heating

#

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| UPD75516 | 4-BIT, SINGLE-CHIP CMOS MICROCOMPUTER WITH EXTENSIVE I/O AND A/D CONVERTER |

| UPD75516GF-637-3B9 | 4-BIT SINGLE-CHIP MICROCOMPUTER |

| UPD75516GF-076 | 4-BIT SINGLE-CHIP MICROCOMPUTER |

| UPD75516GF-079 | 4-BIT SINGLE-CHIP MICROCOMPUTER |

| UPD75516GF-102 | 4-BIT SINGLE-CHIP MICROCOMPUTER |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| UPD753012AGC-P33-8BT-A | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD753016AGC-P29-8BT | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD75304GF-407-3B9 | 制造商:Renesas Electronics Corporation 功能描述: |

| UPD75306G182 | 制造商:Panasonic Industrial Company 功能描述:IC |

| UPD75308F478 | 制造商:Panasonic Industrial Company 功能描述:IC |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。