- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄97930 > EPIC EPiC Family Product Line (304k) PDF資料下載

參數(shù)資料

| 型號: | EPIC |

| 英文描述: | EPiC Family Product Line (304k) |

| 中文描述: | 史詩系列產(chǎn)品線(304k) |

| 文件頁數(shù): | 2/12頁 |

| 文件大?。?/td> | 304K |

| 代理商: | EPIC |

10

www.semtech.com

HIGH PERFORMANCE PRODUCTS

Revision 1/December 3, 2001

AN1001

The junction temperature may be predicted by the equa-

tion:

T

J

= T

A

+

q

JA

* P

D

However, T

J

of any EPiC product will vary over a wide

range, depending on the environment. The power con-

sumption is a function of the total supply voltage (VCC

- VEE) and the particular output configuration (open

emitter, series termination) selected. Thermal resis-

tance

q

JA

, is heavily dependent upon the particular cool-

ing technique used.

Not all parts may be used reliable for all cooling

schemes or power supply conditions. The EPiC Prod-

uct Line is optimized to provide the most integration

and performance for environments using either liquid

(or cold plate) cooling, or air flow >300 LFPM. How-

ever, the 15XX, 19XX and 44XX families all have sev-

eral low power options which can be used with little or

no forced cooling.

The actual

q

JA

will be different for each particular envi-

ronment. However, estimates of typical

q

JA

performance

in several common cooling environments are provided.

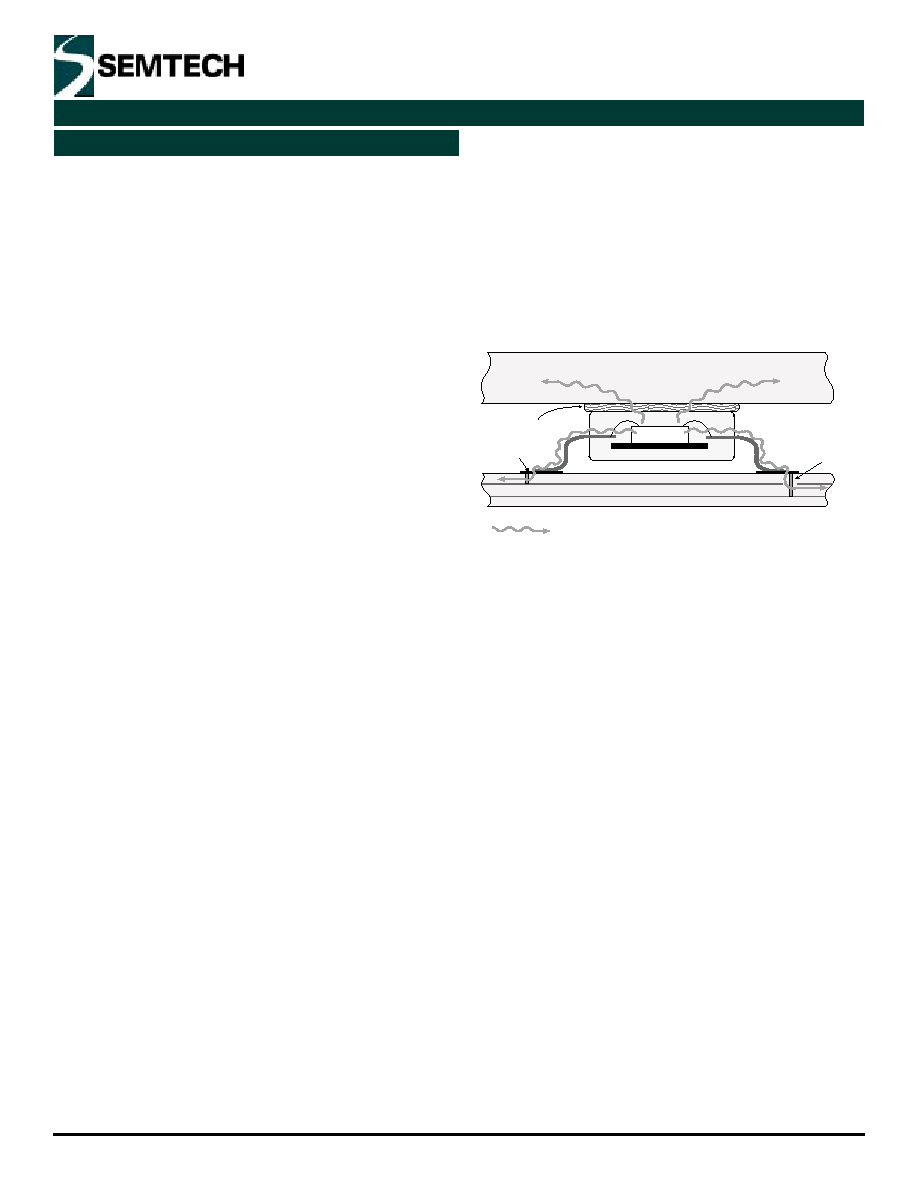

Liquid Cooling

In the liquid cooling environment there is no airflow. All

cooling is achieved via conduction through the top of

the package into a cold plate as well as though the lead

frame down into the power planes inside of the printed

circuit board.

Thermal Analysis

DIE

TJ

19XX, 15XX, 44XX

Thermal

Compound

Air Gap

Pad

Power Plane

PC Board

Power Plane

COLD PLATE

TA

Heat Flow

vias

The following assumptions are made:

1)

the part is soldered to a multilayer PC board

with internal power planes

2)

the part is attached directly to the cold plate on

the top side of the package.

Orthogonal Air Flow

Orthogonal air flow is an environment where cold air

flows directly down to the top of the package. In this

case, cooling is achieved via convection as the cold air

absorbs the heat at the top of the package and carries

the heat out on the side, as well as via conduction

through the lead frame down into the power planes in-

side the printed circuit board. This cooling scheme pro-

duces the lowest thermal resistance for any air cooled

scheme.

The flowing assumptions are made:

1)

the part is soldered to a multilayer PC board

with internal power planes

2)

no heat sink.

In this environment,

q

JA

,

@ 30oC / watt.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| EPL10P8BD | UV-Erasable/OTP PLD |

| EPL10P8BP | UV-Erasable/OTP PLD |

| EPL12P6BD | UV-Erasable/OTP PLD |

| EPL241ED | UV-Erasable/OTP PLD |

| EPL241EJ | UV-Erasable/OTP PLD |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| EPIC1741GW | 制造商:Vishay Semiconductors 功能描述: |

| EPIC3T144C8 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:技術(shù)資料 |

| EPIC-5536 | 制造商:AAEON 制造商全稱:AAEON 功能描述:EPIC Board with Onboard AMD Geode LX800 (500 MHz) Processor |

| EPIC-5537 | 制造商:AAEON 制造商全稱:AAEON 功能描述:Onboard AMD Geodea?¢ LX 800 Processor |

| EPIC-5537W1 | 制造商:AAEON 制造商全稱:AAEON 功能描述:Onboard AMD Geodea?¢ LX 800 Processor 500 MHz |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。