- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄372115 > SAA7370A (NXP SEMICONDUCTORS) Digital servo processor and Compact Disc decoder CD7 PDF資料下載

參數(shù)資料

| 型號: | SAA7370A |

| 廠商: | NXP SEMICONDUCTORS |

| 元件分類: | 消費(fèi)家電 |

| 英文描述: | Digital servo processor and Compact Disc decoder CD7 |

| 中文描述: | SPECIALTY CONSUMER CIRCUIT, PQFP64 |

| 封裝: | 14 X 14 MM, 2.70 MM HEIGHT, PLASTIC, MS-022, SOT-393-1, QFP-64 |

| 文件頁數(shù): | 23/60頁 |

| 文件大小: | 248K |

| 代理商: | SAA7370A |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁當(dāng)前第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁

1998 Feb 26

23

Philips Semiconductors

Product specification

Digital servo processor and Compact Disc

decoder (CD7)

SAA7370A

7.13.1.4

CDV/CAV output mode

In the CDV motor mode, the FIFO position will be put in

pulse-width modulated form on the MOTO1 pin [carrier

frequency (300

×

d) Hz], where ‘d’ is the disc speed factor.

The PLL frequency signal will be put in pulse-density

modulated form (carrier frequency 4.23

×

n MHz) on the

MOTO2 pin. The integrated motor servo is disabled in this

mode.

The PWM signal on MOTO1 corresponds to a total

memory space of 20 frames, therefore the nominal FIFO

position (half full) will result in a PWM output of 60%.

In the lock to-disc (CAV) mode the CDV motor mode is the

only mode that can be used to control the motor.

7.13.2

S

PINDLE MOTOR OPERATING MODES

The operation modes of the motor servo is controlled by

register 1 (see Table 9).

In the SAA7370A decoder there is an anti-windup mode for

the motor servo, selected via register 1. When the

anti-wind-up mode is activated the motor servo integrator

will hold if the motor output saturates.

7.13.2.1

Power limit

In start mode 1, start mode 2, stop mode 1 and stop

mode 2, a fixed positive or negative voltage is applied to

the motor.

This voltage can be programmed as a percentage of the

maximum possible voltage, via register 6, to limit current

drain during start and stop.

The following power limits are possible;

100% (no power limit), 75%, 50%, or 37% of maximum.

7.13.3

L

OOP CHARACTERISTICS

The gain and crossover frequencies of the motor control

loop can be programmed via registers 4 and 5.

The following parameter values are possible;

Gains: 3.2, 4.0, 6.4, 8.0, 12.8, 16, 25.6 and 32

Crossover frequency f

4

: 0.5

×

n Hz, 0.7

×

n Hz,

1.4

×

n Hz, 2.8

×

n Hz

Crossover frequency f

3

: 0.85

×

n Hz, 1.71

×

n Hz,

3.42

×

n Hz

It should be noted that the crossover frequencies f

3

and f

4

are scaled with the overspeed factor ‘n’ whereas the gains

are not.

7.13.4

FIFO

OVERFLOW

If FIFO overflow occurs during Play mode (e.g.: as a result

of motor rotational shock), the FIFO will be automatically

reset to 50% and the audio interpolator tries to conceal as

much as possible to minimise the effect of data loss.

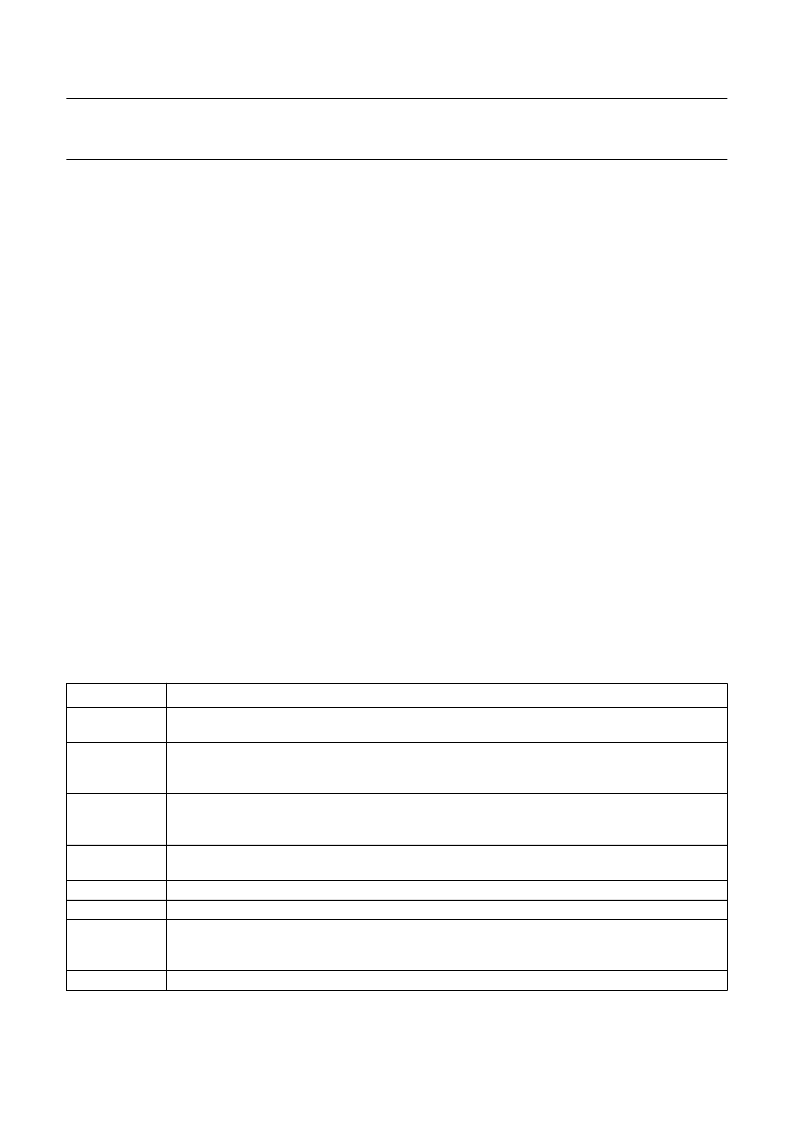

Table 9

Operating modes

MODE

DESCRIPTION

Start mode 1

The disc is accelerated by applying a positive voltage to the spindle motor. No decisions are

involved and the PLL is reset. No disc speed information is available for the microcontroller.

The disc is accelerated as in start mode 1, however the PLL will monitor the disc speed. When the

disc reaches 75% of its nominal speed, the controller will switch to jump mode. The motor status

signals selectable via register 2 are valid.

Motor servo enabled but FIFO kept reset at 50%, integrator is held. The audio is muted but it is

possible to read the subcode. It should be noted that in the CD-ROM modes the data, on EBU and

the I

2

S-bus is not muted.

Similar to jump mode but motor integrator is kept at zero. Used for long jumps where there is a large

change in disc speed.

FIFO released after resetting to 50%. Audio mute released.

Disc is braked by applying a negative voltage to the motor. No decisions are involved.

The disc is braked as in stop mode 1 but the PLL will monitor the disc speed. As soon as the disc

reaches 12% (or 6%, depending on the programmed brake percentage, via register E) of its

nominal speed, the MOTSTOP status signal will go HIGH and switch the motor servo to Off mode.

Motor not steered.

Start mode 2

Jump mode

Jump mode 1

Play mode

Stop mode 1

Stop mode 2

Off mode

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| SAA7370 | Digital servo processor and Compact Disc decoder CD7 |

| SAA7371 | Digital servo processor and Compact Disc decoder CD7 |

| SAA7371GP | Digital servo processor and Compact Disc decoder CD7 |

| SAA7372 | Digital servo processor and Compact Disc decoder CD7 |

| SAA7373 | Digital servo processor and Compact Disc decoder CD7 |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| SAA7371 | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Digital servo processor and Compact Disc decoder CD7 |

| SAA7371GP | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Digital servo processor and Compact Disc decoder CD7 |

| SAA7372 | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Digital servo processor and Compact Disc decoder CD7 |

| SAA7373 | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Digital servo processor and Compact Disc decoder CD7 |

| SAA7373GP | 制造商:PHILIPS 制造商全稱:NXP Semiconductors 功能描述:Digital servo processor and Compact Disc decoder CD7 |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。