- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄385394 > HSDL-3602-038 (Avago Technologies Ltd.) IrDA㈢ Data 1.4 Compliant 4 Mb/s 3V Infrared Transceiver PDF資料下載

參數(shù)資料

| 型號: | HSDL-3602-038 |

| 廠商: | Avago Technologies Ltd. |

| 英文描述: | IrDA㈢ Data 1.4 Compliant 4 Mb/s 3V Infrared Transceiver |

| 中文描述: | ㈢數(shù)據(jù)的IrDA 1.4兼容4 Mb / s的3V的紅外收發(fā)器 |

| 文件頁數(shù): | 13/27頁 |

| 文件大小: | 388K |

| 代理商: | HSDL-3602-038 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁當(dāng)前第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁

13

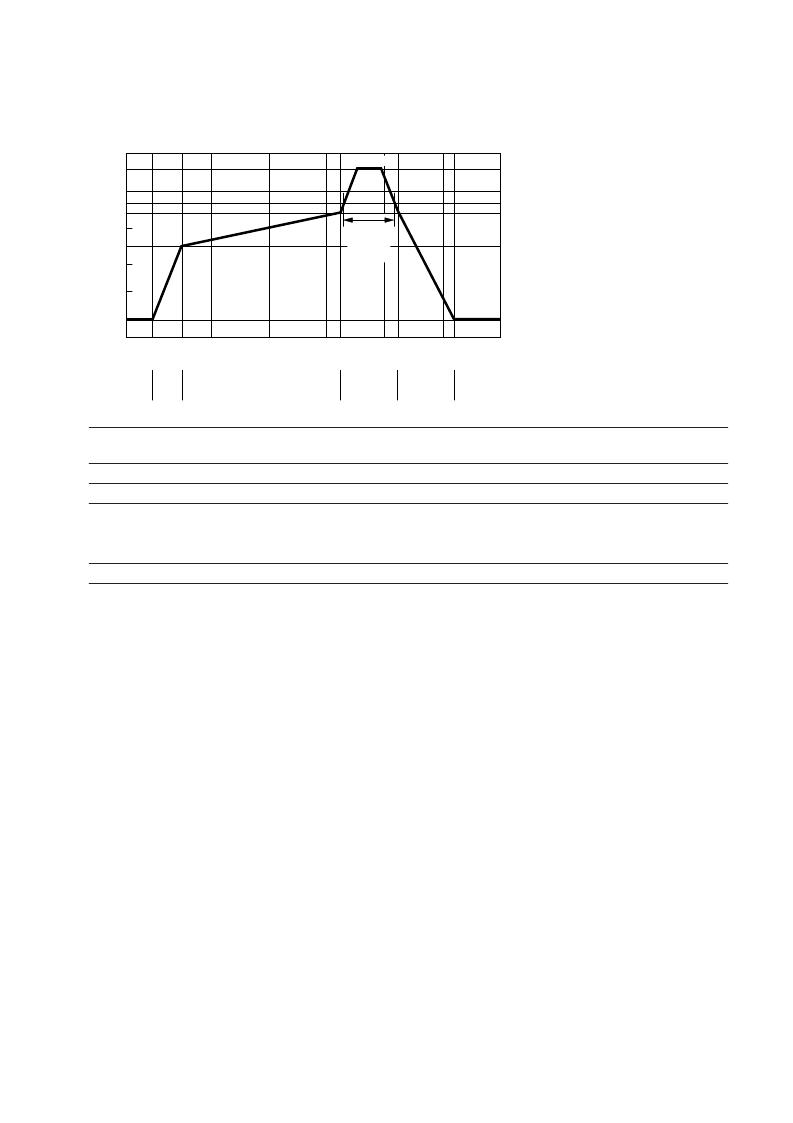

The reflow profile is a straight-line representation of

a nominal temperature profile for a convective reflow

solder process. The temperature profile is divided into

four process zones, each with different T/time tem-

perature change rates. The T/time rates are detailed

in the following table. The temperatures are measured

at the component to printed circuit board connections.

In process zone P1, the PC board and HSDL-3602 cas-

tellation pins are heated to a temperature of 160°C to

activate the flux in the solder paste. The temperature

ramp up rate, R1, is limited to 4°C per second to allow

for even heating of both the PC board and HSDL-3602

castellations.

Process zone P2 should be of sufficient time duration

(60 to 120 seconds) to dry the solder paste. The tem-

perature is raised to a level just below the liquidus point

of the solder, usually 200°C (392°F).

Process zone P3 is the solder reflow zone. In zone P3, the

temperature is quickly raised above the liquidus point

of solder to 255°C (491°F) for optimum results. The

dwell time above the liquidus point of solder should

Process Zone

Heat Up

Solder Paste Dry

Solder Reflow

Cool Down

Symbol

P1, R1

P2, R2

P3, R3

P3, R4

P4, R5

T

25C to 160C

160C to 200C

200C to 255C

(260C at 10 seconds max.)

255C to 200C

200C to 25C

Maximum

T/time

4C/s

0.5C/s

4C/s

–6C/s

–6C/s

Recommended Reflow Profile

be between 20 and 60 seconds. It usually takes about

20 seconds to assure proper coalescing of the solder

balls into liquid solder and the formation of good solder

connections. Beyond a dwell time of 60 seconds, the

intermetallic growth within the solder connections be-

comes excessive, resulting in the formation of weak and

unreliable connections. The temperature is then rapidly

reduced to a point below the solidus temperature of

the solder, usually 200°C (392°F), to allow the solder

within the connections to freeze solid.

Process zone P4 is the cool down after solder freeze. The

cool down rate, R5, from the liquidus point of the solder

to 25°C (77°F) should not exceed 6°C per second maxi-

mum. This limitation is necessary to allow the PC board

and HSDL-3602 castellations to change dimensions

evenly, putting minimal stresses on the HSDL-3602

transceiver.

0

t-TIME (SECONDS)

T

230

220

200

180

160

120

80

50

150

100

200

250

300

255

P1

HEAT

UP

P2

SOLDER PASTE DRY

P3

SOLDER

REFLOW

P4

COOL

DOWN

25

R1

R2

R3

R4

R5

60 sec.

MAX.

ABOVE

220 C

MAX. 260 C

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HSDL-3603 | IrDA㈢ Data Compliant 4 Mbit/s Infrared Transceiver |

| HSDL-3603-207 | IrDA㈢ Data Compliant 4 Mbit/s Infrared Transceiver |

| HSDL-3603-208 | IrDA㈢ Data Compliant 4 Mbit/s Infrared Transceiver |

| HSDL-4250 | High-Performance T-1 (5mm) AlGaAs Infrared (870nm) Lamp |

| HSDL-4251 | High-Performance T-1 (5mm) AlGaAs Infrared (870nm) Lamp |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HSDL-3603 | 制造商:AVAGO 制造商全稱:AVAGO TECHNOLOGIES LIMITED 功能描述:IrDA㈢ Data Compliant 4 Mbit/s Infrared Transceiver |

| HSDL-3603-007 | 制造商:Lite-On Semiconductor Corporation 功能描述:IRDA TX/RX 4MBPS 2.7V TO 5.25V - Bulk 制造商:Avago Technologies 功能描述:TRANSCEIVER SMD IRDA1.4 4MB |

| HSDL-3603-007 | 制造商:Avago Technologies 功能描述:TRANSCEIVER SMD IRDA1.4 4MB |

| HSDL-3603-017 | 制造商:Lite-On Semiconductor Corporation 功能描述:IRDA TX/RX 4MBPS 3.3V/5V - Bulk |

| HSDL-3603-207 | 制造商:AVAGO 制造商全稱:AVAGO TECHNOLOGIES LIMITED 功能描述:IrDA㈢ Data Compliant 4 Mbit/s Infrared Transceiver |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。