- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄359893 > 43184&43181 Dual/Triple Ultra-Low-Voltage SOT23 µP Supervisory Circuits PDF資料下載

參數(shù)資料

| 型號: | 43184&43181 |

| 英文描述: | Dual/Triple Ultra-Low-Voltage SOT23 µP Supervisory Circuits |

| 中文描述: | 扭力測試儀20-400 |

| 文件頁數(shù): | 3/12頁 |

| 文件大小: | 255K |

| 代理商: | 43184&43181 |

PRO-TEST OPERATORS HANDBOOK

PAGE 1 OF 10

ISSUE 4

AUGUST 1998

INTRODUCTION

The Professional Torque Tester (Pro-Test) has been designed as an accurate, cost effective

and easy to operate instrument for testing and calibrating all types of torque wrenches and torque

limiting screw drivers.

Pro-Test transducers are mounted in aluminium cast housings along with all the necessary

electronics to produce an output for the display module and RS-232-C interface. The housings can

be mounted for either horizontal, clockwise, or anti-clockwise torque testing.

The function of the front panel buttons is identified on the display to facilitate quick and easy

selection of the operating mode most suitable for the tool to be tested, i.e. track, peak memory with

manual reset, peak memory with auto reset, first peak memory with manual reset, or first peak

memory with auto reset. These buttons are also used to drive the Set-up Menus if changes to the

operational parameters of the Pro-Test are required. These include, language of operation,

measurement units to be enabled/disabled, RS-232-C communication parameters, auto reset hold

time, first peak memory sensitivity and modes of operation to be enabled/disabled. The Zero button is

only active in the track mode.

Pro-Test transducers are calibrated in the clockwise direction only as standard, the anti-

clockwise direction of operation will be inhibited unless the transducer has been additionally calibrated

in this direction. The direction of use is identified on the display and RS232C output

Optional extra’s include a Mounting Bracket, 1” sq x 36mm Hex Socket, Print Inhibit

Controller, Data Printer and 12 Volt DC power supply for use in vehicles.

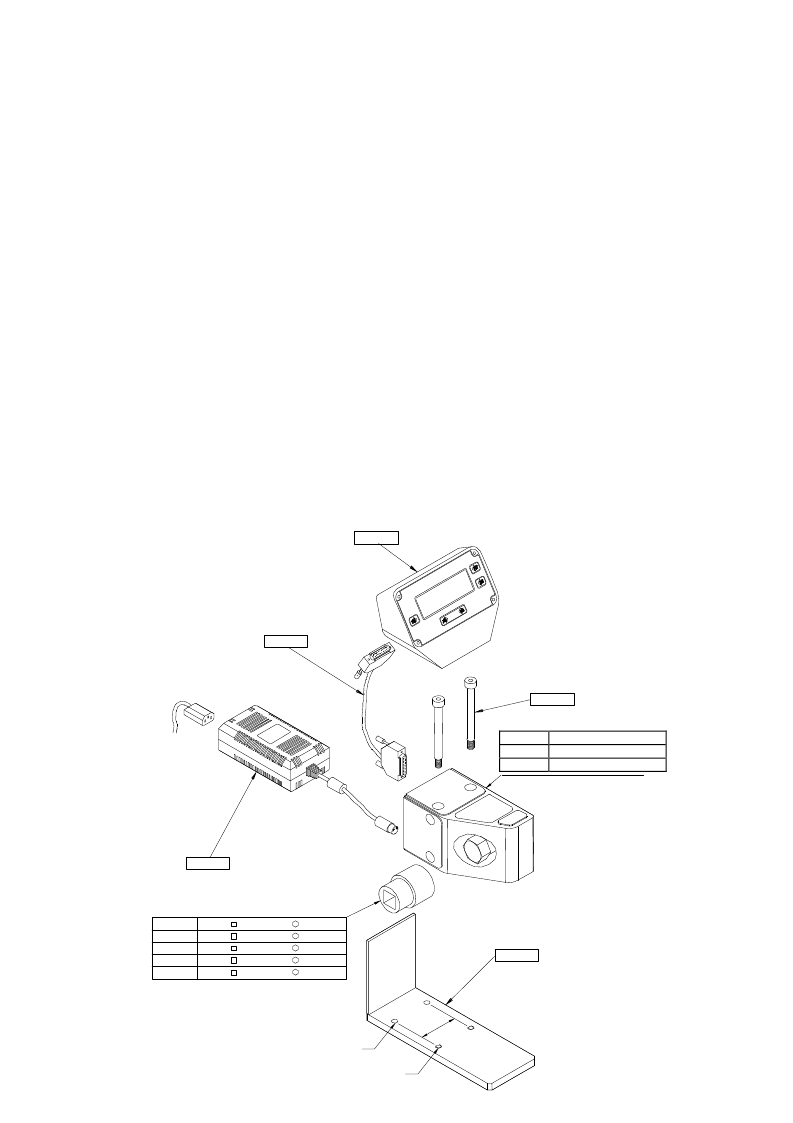

ASSEMBLY DIAGRAM

43184

38793

62198 (OPTIONAL)

70

2 HOLES M10

38796

29179 3/4" TO 36mm SOCKET

29190 1" TO 36mm SOCKET

29189 3/4" TO 22mm SOCKET

29134 1/2" TO 22mm SOCKET

29067 3/8" TO 10mm SOCKET

2 HOLES

10

25429

43180 PRO-TEST 40

43181 PRO-TEST 400

43182 PRO-TEST 1000

43183 PRO-TEST 1500

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 431LP4E | MMIC VCO w/ BUFFER AMPLIFIER, 5.5 - 6.1 GHz |

| 431PADS1X12X25MM | KLEBEKISSEN BOX 300 Inhalt pro Packung: 300 Stk. |

| 431 | Surface Mount Fuses - Thin-Film Surface Mount |

| 432-0100-1 | Dual/Triple Ultra-Low-Voltage SOT23 µP Supervisory Circuits |

| 432-0500-1 | BUCHSE CINCH GOLDAUFLAGE 0.5U ROT |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 4318550001 | 制造商:TE Connectivity 功能描述:RPS-2.5K-18-12/2.0-S2-9 - Bulk |

| 4-318711-0 | 制造商:TE Connectivity 功能描述:ANVIL, COMBINATION - Bulk |

| 4-318711-1 | 制造商:TE Connectivity 功能描述:ANVIL, COMBINATION - Bulk |

| 4-318711-2 | 功能描述:折皺器 ANVIL, COMBINATION RoHS:否 制造商:Hirose Connector 類型: 描述/功能:Cable and Shield Crimper |

| 4-318711-3 | 功能描述:折皺器 ANVIL, COMBINATION RoHS:否 制造商:Hirose Connector 類型: 描述/功能:Cable and Shield Crimper |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。