- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄371968 > R485 R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications PDF資料下載

參數(shù)資料

| 型號(hào): | R485 |

| 英文描述: | R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications |

| 中文描述: | R485型光波接收機(jī)2.488磁錄密度/有時(shí)鐘恢復(fù)s應(yīng)用 |

| 文件頁(yè)數(shù): | 2/10頁(yè) |

| 文件大?。?/td> | 134K |

| 代理商: | R485 |

2

Agere Systems Inc.

Advance Data Sheet, Rev. 1

October 2001

Recovery for 2.488 Gbits/s Applications

R485-Type Lightwave Receiver with Clock

Flag Output

When the incoming optical signal falls below the link-

status switching threshold, the FLAG output is asserted

and the FLAG output logic level changes from a TTL

low to a TTL high.

Pin Information

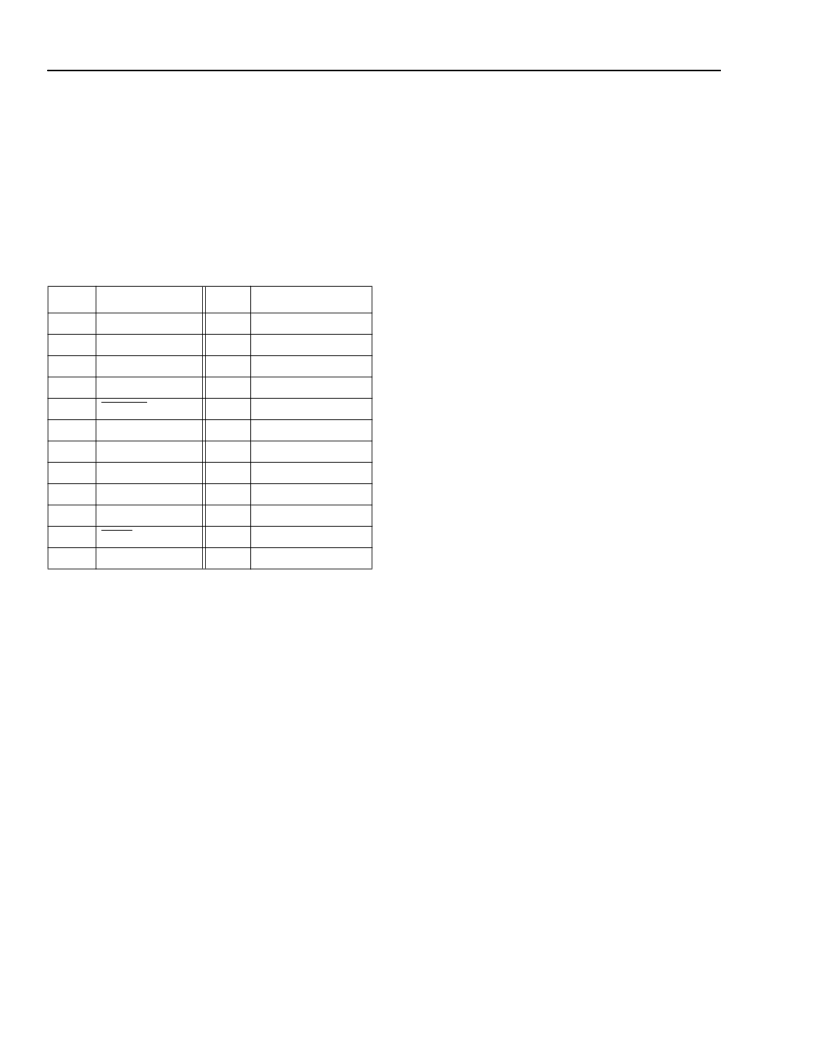

Table 1. Pin Information

* Pins designated as no user connect (NUC) are connected inter-

nally. The user should not make any connections to these pins.

The loss of signal (LOS) FLAG output is a logic level that indicates

the presence or absence of a minimum acceptable level of optical

input. A TTL logic HIGH indicates the absence of a valid optical

input signal.

This pin is not internally connected if the amplitude decision

threshold (DTV) is not made adjustable.

Handling Precautions

The R485-Type receiver is manufactured with a

39 in.

±

4 in. (100 cm

±

10 cm) single-mode fiber pigtail

with a 900

μ

m OD PVC outer jacket. Both SC and FC-

PC connectors are offered on standard versions. Other

optical connector options are available on special

order. Please contact an Agere Systems Account Man-

ager for availability and ordering information.

The minimum fiber bending radius is 1.5 inches

(38 mm).

Receiver Processing

The R485-Type receiver devices can withstand normal

wave soldering processes. The complete receiver mod-

ule is not hermetically sealed; therefore, it should not

be immersed in, or sprayed with, any solutions. The

optical connector process cap deformation temperature

is 85

°

C. The receiver pins can be wave soldered at

250

°

C for 10 seconds.

Electrostatic Discharge

CAUTION: This device is susceptible to damage as

a result of electrostatic discharge (ESD).

Take proper precautions during both

handling and testing. Follow guidelines

such as JEDEC Publication No. 108-A

(Dec. 1988).

Although protection circuitry is designed into the

device, take proper precautions to avoid exposure to

ESD.

Agere employs a human-body model HBM) for ESD-

susceptibility testing and protection design evaluation.

ESD voltage thresholds are dependent on the critical

parameters used to define the model. A standard HBM

(resistance = 1.5 k

, capacitance = 100 pF) is widely

used and, therefore, can be used for comparison pur-

poses.

Installation Considerations

Although the receiver has been designed with rugged-

ness in mind, care should be used during handling.

The optical connector should be kept free from dust.

The optical connector process cap should be kept in

place as a dust cover when the device is not connected

to a cable. If contamination is present on the optical

connector, the use of canned air with a extension tube

should remove any loose debris. Other cleaning proce-

dures are outlined in the Cleaning Fiber Optic Assem-

bliesTechnical Note (TN95-010LWP).

The cable should be handled conservatively with no

excessive axial pulling or lateral tugging.

Pin

Name

Pin

Name

1

2

3

4

5

6

7

8

9

10

11

12

NIC

NUC*

LOS Flag

Ground

CLOCK

CLOCK

Ground

V

CC

Ground

DATA

DATA

Ground

24

23

22

21

20

19

18

17

16

15

14

13

NUC*

NUC*

V

CC

NUC*

Ground

Ground

NIC

Ground

Ground

Ground

Ground

DTV/NIC

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| R485WPBB | DIODE ZENER SINGLE 200mW 16.1Vz 10mA-Izt 0.02547 0.05uA-Ir 12 SOD-323 3K/REEL |

| R485WPAA | R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications |

| R485CMAA | R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications |

| R485CPAA | R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications |

| R485CPBB | R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| R4850-T2D512 | 制造商:Micro-Star International 功能描述:MSI HD 4850, 512MB - Bulk |

| R4858446-18 | 制造商:n/a 功能描述:Power Module |

| R48-5A5-120 | 制造商:NTE Electronics 功能描述:RELAY-5AMP-A/C 120V |

| R485CMAA | 制造商:AGERE 制造商全稱:AGERE 功能描述:R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications |

| R485CPAA | 制造商:AGERE 制造商全稱:AGERE 功能描述:R485-Type Lightwave Receiver with Clock Recovery for 2.488 Gbits/s Applications |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。