- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄296762 > PA35 Operational Amplifier PDF資料下載

參數(shù)資料

| 型號: | PA35 |

| 英文描述: | Operational Amplifier |

| 中文描述: | 運(yùn)算放大器 |

| 文件頁數(shù): | 4/4頁 |

| 文件大小: | 69K |

| 代理商: | PA35 |

APEX MICROTECHNOLOGY CORPORATION 5980 NORTH SHANNON ROAD TUCSON, ARIZONA 85741 USA APPLICATIONS HOTLINE: 1 (800) 546-2739

OPERATING

CONSIDERATIONS

PA35

GENERAL

Please read Application Note 1 "General Operating

Considerations" which covers stability, supplies, heat sinking,

mounting, current limit, SOA interpretation, and specication

interpretation. Visit www.apexmicrotech.com for design tools

that help automate tasks such as calculations for stability,

internal power dissipation, current limit and heat sink

selection. The "Application Notes" and "Technical Seminar"

sections contain a wealth of information on specic types of

applications.Package outlines, heat sinks, mounting hardware

and other accessories are located in the "Packages and

Accessories" section. Evaluation Kits are available for most

Apex product models, consult the "Evaluation Kit" section for

details. For the most current version of all Apex product data

sheets, visit www.apexmicrotech.com.

CURRENT LIMIT

Current limit is internal to the amplier, the typical value is

shown in the current limit specication.

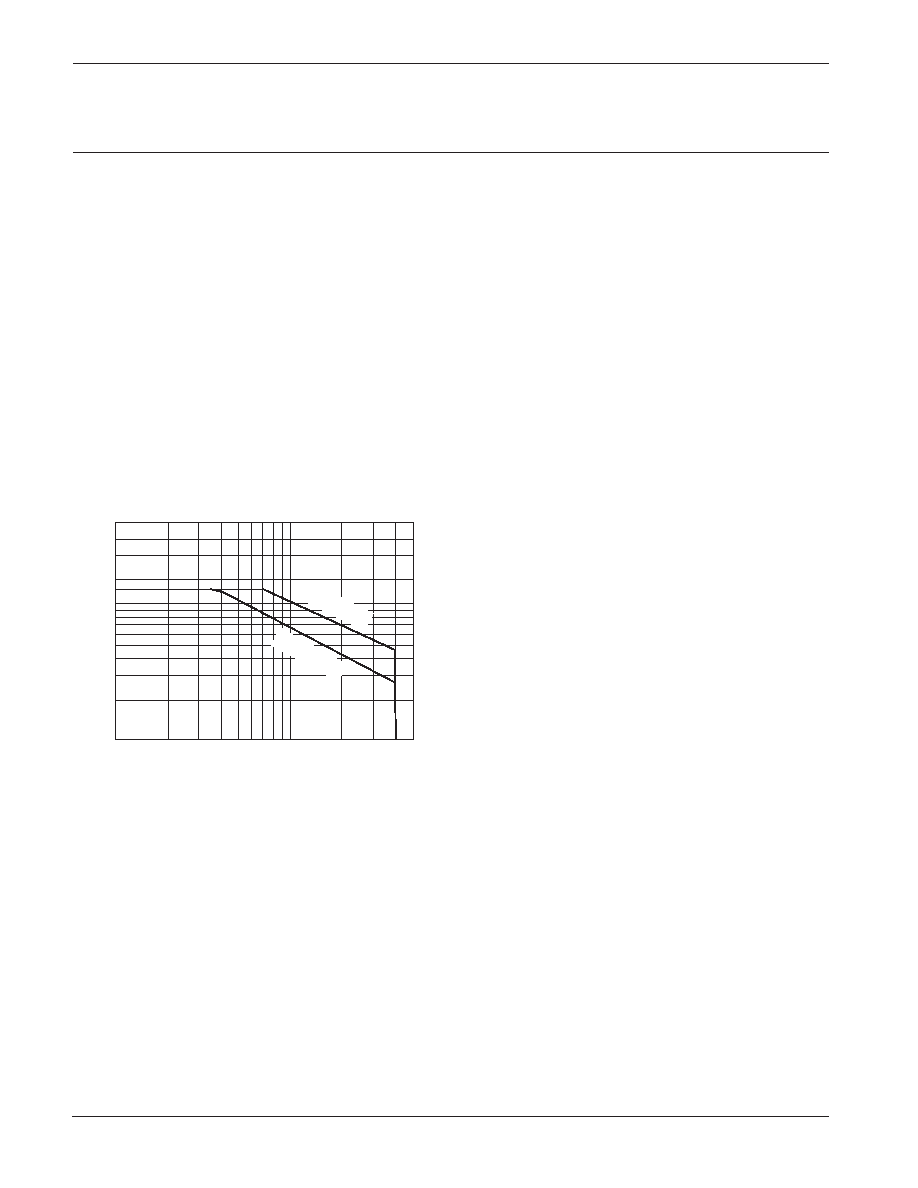

SAFE OPERATING AREA (SOA)

The SOA curves combine the effect of all limits for this

power op amp. For a given application, the direction and

magnitude of the output current should be calculated or

measured and checked against the SOA curves. This is

simple for resistive loads but more complex for reactive and

EMF generating loads. The following guidelines may save

extensive analytical efforts.

Under transient conditions, capacitive and dynamic*

inductive loads up to the following maximum are safe:

±Vs

CAPACITIVE LOAD

INDUCTIVE LOAD

20V

200F

7.5mH

15V

500F

25mH

10V

5mF

35mH

5V

50mF

150mH

* If the inductive load is driven near steady state conditions,

allowing the output voltage to drop more than 6V below the

supply rail while the amplier is current limiting, the inductor

should be capacitively coupled or the supply voltage must be

lowered to meet SOA criteria.

NOTE: For protection against sustained, high energy yback,

external fast-recovery diodes should be used.

MONOLITHIC AMPLIFIER

STABILITY CONSIDERATIONS

All monolithic power op amps use output stage topologies

that present special stability problems. This is primarily due

to non-complementary (both devices are NPN) output

stages with a mismatch in gain and phase response for

different polarities of output current. It is difcult for the

op amp manufacturer to optimize compensation for all

operating conditions.

The recommended R-C network of 1 ohm in series with

0.1F from output to AC common (ground or a supply rail,

with adequate bypass capacitors) will prevent local output

stage oscillations.

The ampliers are internally compensated for unity gain

stability, no additional compensation is required.

THERMAL CONSIDERATIONS

The PA35 may require a thermal washer which is electrically

insulating since the tab is tied to –VS.This can result in thermal

impedances for R θCS of up to 1°C/W or greater.

VBIAS should be set midway between +Vs and -Vs, Vref

is usually ground in dual supply systems or used for level

translation in single supply systems.

MOUNTING PRECAUTIONS

1. Always use a heat sink. Even unloaded, the PA35 can

dissipate up to 3.6 watts. An insulating thermal washer

should always be used.

2. Avoid bending the leads. Such action can lead to internal

damage.

3. Always fasten the tab to the heat sink before the leads are

soldered to xed terminals.

4. Strain relief must be provided if there is any probability of

axial stress to the leads.

4

3

2

1

.1

12

3

4

5

7 8 9

610

20

30

SUPPLY TO OUTPUT DIFFERENTIAL VOLTAGE V –V (V)

SO

OUTPUT

CURRENT

FROM

+V

OR

–V

(A)

SS

40

5

T

= 85

°C

C

DC,

T

= 25°

C

DC,

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specications are subject to change without notice.

PA35U REV. A MARCH 2001 2001 Apex Microtechnology Corp.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| PA37 | Analog IC |

| PA4-5PD11J-D01 | 9 CONTACT(S), MALE, STRAIGHT TWO PART BOARD CONNECTOR, SOLDER, PLUG |

| PA4-5PD11J-P39 | 9 CONTACT(S), MALE, STRAIGHT TWO PART BOARD CONNECTOR, SOLDER, PLUG |

| PA4-5PD11JT-D01 | 9 CONTACT(S), MALE, STRAIGHT TWO PART BOARD CONNECTOR, SOLDER, PLUG |

| PA4-5PD11JT-P39 | 9 CONTACT(S), MALE, STRAIGHT TWO PART BOARD CONNECTOR, SOLDER, PLUG |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| PA-35 | 制造商:CENTRALAB 功能描述: 制造商:Electro Switch Corp 功能描述: |

| PA350 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:RISING CLAMP TERMINAL BLOCK |

| PA351 | 功能描述:按鈕開關(guān) ON-OFF .250 QC TAB RoHS:否 制造商:C&K Components 觸點(diǎn)形式:2 NC - 2 NO 開關(guān)功能:ON ? OFF 電流額定值:4 A 電壓額定值 AC:12 V to 250 V 電壓額定值 DC:12 V to 50 V 功率額定值: 安裝風(fēng)格:Through Hole 照明:Illuminated 照明顏色:None IP 等級:IP 40 端接類型:Solder 觸點(diǎn)電鍍:Silver 執(zhí)行器:Square 蓋顏色: 封裝: 可燃性等級:UL 94 V-0 |

| PA35-13 | 功能描述:ANT PNL TRI 13DBI 3.5GHZ N FEM RoHS:是 類別:RF/IF 和 RFID >> RF 天線 系列:* 標(biāo)準(zhǔn)包裝:1 系列:* |

| PA35135-1 | 制造商:Alpha 3 Manufacturing 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。