- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄369938 > P2202Z solid state crowbar devices PDF資料下載

參數(shù)資料

| 型號: | P2202Z |

| 英文描述: | solid state crowbar devices |

| 中文描述: | 固態(tài)撬棍設(shè)備 |

| 文件頁數(shù): | 185/212頁 |

| 文件大小: | 1877K |

| 代理商: | P2202Z |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁第85頁第86頁第87頁第88頁第89頁第90頁第91頁第92頁第93頁第94頁第95頁第96頁第97頁第98頁第99頁第100頁第101頁第102頁第103頁第104頁第105頁第106頁第107頁第108頁第109頁第110頁第111頁第112頁第113頁第114頁第115頁第116頁第117頁第118頁第119頁第120頁第121頁第122頁第123頁第124頁第125頁第126頁第127頁第128頁第129頁第130頁第131頁第132頁第133頁第134頁第135頁第136頁第137頁第138頁第139頁第140頁第141頁第142頁第143頁第144頁第145頁第146頁第147頁第148頁第149頁第150頁第151頁第152頁第153頁第154頁第155頁第156頁第157頁第158頁第159頁第160頁第161頁第162頁第163頁第164頁第165頁第166頁第167頁第168頁第169頁第170頁第171頁第172頁第173頁第174頁第175頁第176頁第177頁第178頁第179頁第180頁第181頁第182頁第183頁第184頁當前第185頁第186頁第187頁第188頁第189頁第190頁第191頁第192頁第193頁第194頁第195頁第196頁第197頁第198頁第199頁第200頁第201頁第202頁第203頁第204頁第205頁第206頁第207頁第208頁第209頁第210頁第211頁第212頁

SIDACtor Soldering Recommendations

2002 Teccor Electronics

SIDACtor

Data Book and Design Guide

5 - 23

http://www.teccor.com

+1 972-580-7777

T

not exceed 275 °C and the maximum temperature of the plastic body does not exceed

250 °C. (Figure 5.8)

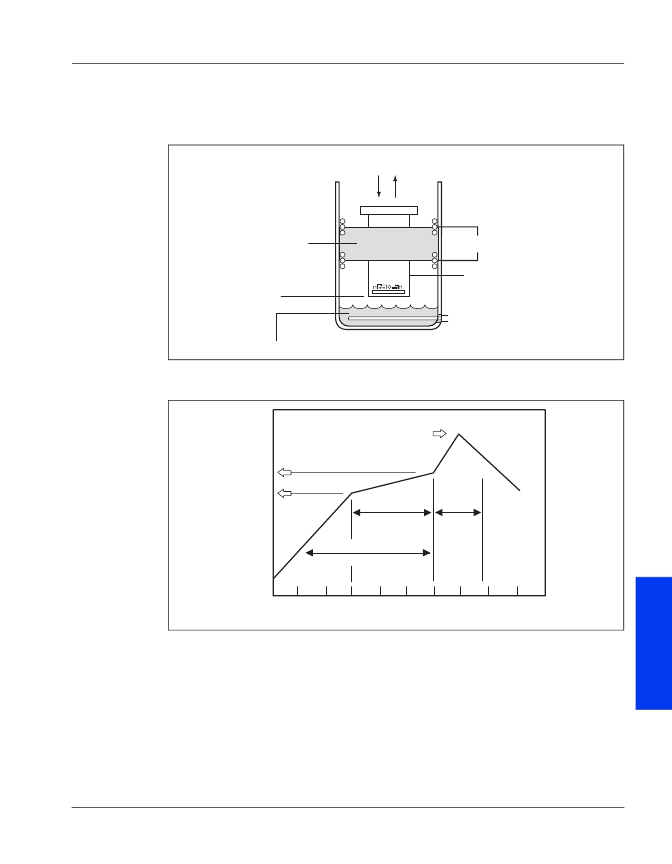

Figure 5.7

Principle of Vapor Phase Soldering

Figure 5.8

Reflow Soldering Profile

During reflow, the surface tension of the liquid solder draws the leads of the device towards

the center of the soldering area, correcting any misalignment that may have occurred

during placement and allowing the device to set flush on the pad. If the footprints of the pad

are not concentrically aligned, the same effect can result in undesirable shifts as well.

Therefore, it is important to use a standard contact pattern which leaves sufficient room for

self-positioning.

After the solder cools, connections should be visually inspected and remnants of the flux

removed using a vapor degreaser with an azeotrope solvent or equivalent.

Transport

Cooling pipes

PC board

Heating

elements

Boiling liquid (primary medium)

Vapor phase

zone

Vapor lock

(secondary

medium)

Time (Seconds)

0

0

20

40

60

80

100

120

140

160

180

200

220

240

30

60

90

120

150

180

210

240

270

300

T

Pre-heat

Soak

Reflow

Cool

Down

0.5 - 0.6

C/s

1.3 - 1.6

C/s

<2.5

C/s

<2.5

C/s

Peak Temperature

220

C - 245

C

Soaking Zone

Reflow Zone

Pre-heating Zone

( 2-4 min MAX )

( 2 min. MAX )

60 - 90 s typical

( 2 min. MAX )

30 - 60 s typical

260

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| P2304U | solid state crowbar devices |

| P2353A | solid state crowbar devices |

| P2353ACMC | solid state crowbar devices |

| P2353U | solid state crowbar devices |

| P2353Z | solid state crowbar devices |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| P-22-035 | 制造商:Panasonic Industrial Company 功能描述:HARDWARE PKG |

| P2204 | 功能描述:ANT YAGI VHF ECO 220-222MHZ RoHS:是 類別:RF/IF 和 RFID >> RF 天線 系列:* 標準包裝:1 系列:* |

| P22-040 | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Analog IC |

| P22-040I | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Analog IC |

| P22-040K | 制造商:未知廠家 制造商全稱:未知廠家 功能描述:Analog IC |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。