- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄383693 > OPA622AP OP-AMP|SINGLE|BIPOLAR|DIP|14PIN|PLASTIC PDF資料下載

參數(shù)資料

| 型號: | OPA622AP |

| 英文描述: | OP-AMP|SINGLE|BIPOLAR|DIP|14PIN|PLASTIC |

| 中文描述: | 運放|單|雙極|雙酯| 14PIN |塑料 |

| 文件頁數(shù): | 4/18頁 |

| 文件大小: | 335K |

| 代理商: | OPA622AP |

OPA622

4

PAD

FUNCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

Quiescent Current Adjustment

Inverting Analog Input

Non-Inverting Analog Input

NC

NC

–5V Supply

–5V Supply, Output

Inverting Buffer Output

Analog Output

Analog OTA Output

+5V Supply, Output

+5V Supply

Non-Inverting Buffer Output

Substrate Bias:

Negative Supply

NC:

No Connection

Wire Bonding: Gold wire bonding is recommended.

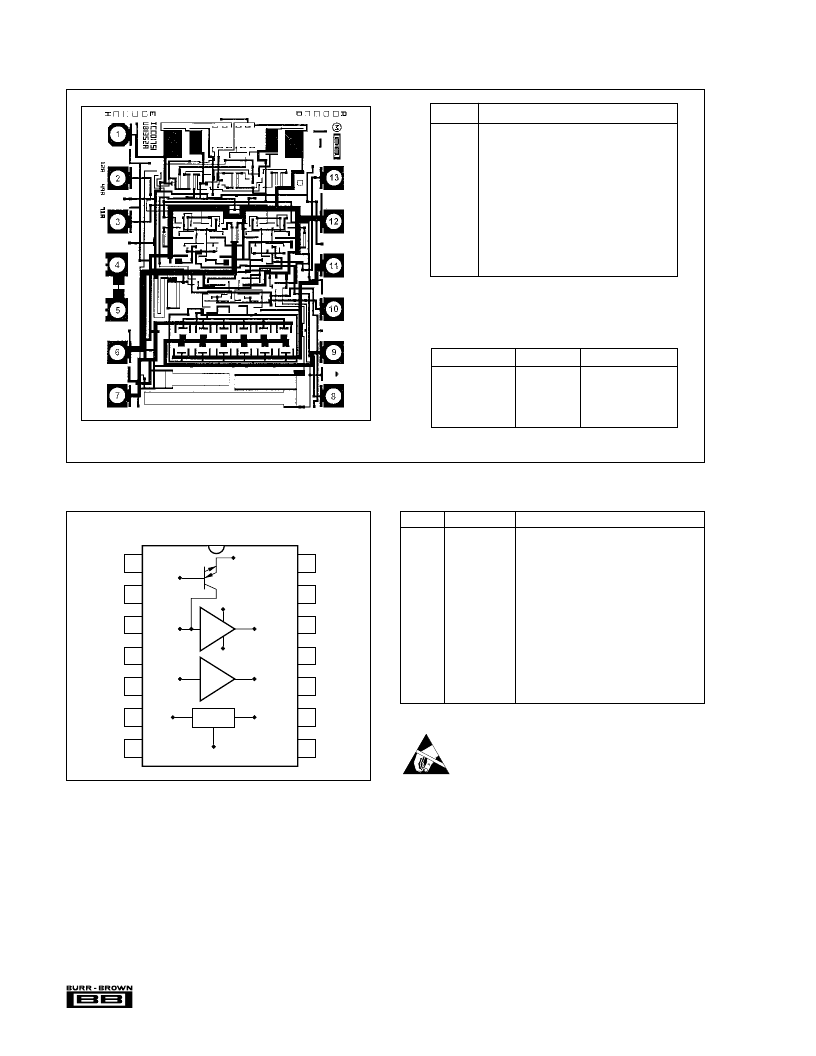

DICE INFORMATION

MECHANICAL INFORMATION

MILS (0.001")

MILLIMETERS

Die Size

Die Thickness

Min. Pad Size

Backing: Titanium

Gold

57 x 69

±

5

14

±

1

4 x 4

0.02+0.05,–0.0

0.30

±

0.05

1.44 x 1.76

±

0.13

0.55

±

0.025

0.10 x 0.10

0.0005+0.0013, –0.0

0.0076

±

0.0013

OPA622AD DIE TOPOGRAPHY

PIN NO.

DESCRIPTION

FUNCTION

1

2

3

4

5

6

NC

No Connection

Quiescent Current Adjustment; typical 3-8mA

Inverting Analog Input

Noninverting Analog Input

Negative Supply Voltage; typical –5VDC

Negative Supply Voltage Output Buffer;

typical –5VDC

Analog Output Feedback Buffer

Analog Output

Analog Output OTA

Positive Supply Voltage Output Buffer; typical

+5VDC

Positive Supply Voltage; typical +5VDC

Analog Output/Input

No Connection

I

Q

Adjust

–In

+In

–V

CC

–V

CC OUT

8

9

BUF–

V

OTA

+V

CC OUT

10

11

12

13

14

+V

BUF+

NC

PIN CONFIGURATION

FUNCTIONAL DESCRIPTION

NC

I

Q

Adjust

–In

+In

–V

CC

–V

CC OUT

NC

NC

BUF+

+V

CC

+V

CC OUT

OTA

V

OUT

BUF–

1

2

3

4

5

6

7

OPA622

14

13

12

11

10

9

8

FB

OTA

OB

13

4

10

3

5

12

2

Biasing

11

6

8

SO/DIP

9

Top View

ELECTROSTATIC

DISCHARGE SENSITIVITY

Electrostatic discharge can cause damage ranging from per-

formance degradation to complete device failure. Burr-

Brown Corporation recommends that all integrated circuits

be handled and stored using appropriate ESD protection

methods.

ESD damage can range from subtle performance degrada-

tion to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet

published specifications.

相關PDF資料 |

PDF描述 |

|---|---|

| OPA622AU | OP-AMP|SINGLE|BIPOLAR|SOP|14PIN|PLASTIC |

| OPA623 | Wide Bandwidth, Current-Feedback OPERATIONAL AMPLIFIER |

| OPA623AP | Wide Bandwidth, Current-Feedback OPERATIONAL AMPLIFIER |

| OPA623AU | Wide Bandwidth, Current-Feedback OPERATIONAL AMPLIFIER |

| OPA628AU | Low Distortion Wideband OPERATIONAL AMPLIFIER |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| OPA622AU | 制造商:BB 制造商全稱:BB 功能描述:Wide-Bandwidth OPERATIONAL AMPLIFIER |

| OPA623 | 制造商:BB 制造商全稱:BB 功能描述:Wide Bandwidth, Current-Feedback OPERATIONAL AMPLIFIER |

| OPA623 WAF | 制造商:Texas Instruments 功能描述: |

| OPA623AP | 制造商:BB 制造商全稱:BB 功能描述:Wide Bandwidth, Current-Feedback OPERATIONAL AMPLIFIER |

| OPA623AU | 制造商:BB 制造商全稱:BB 功能描述:Wide Bandwidth, Current-Feedback OPERATIONAL AMPLIFIER |

發(fā)布緊急采購,3分鐘左右您將得到回復。