- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄371140 > MPX2700AP (MOTOROLA INC) X-ducer SILICON PRESSURE SENSORS PDF資料下載

參數(shù)資料

| 型號(hào): | MPX2700AP |

| 廠商: | MOTOROLA INC |

| 元件分類(lèi): | 壓力傳感器 |

| 英文描述: | X-ducer SILICON PRESSURE SENSORS |

| 中文描述: | ABSOLUTE, PEIZORESISTIVE PRESSURE SENSOR, 0-101.52Psi, 1%, 0.20-4.70V, ROUND, THROUGH HOLE MOUNT |

| 封裝: | CASE 350-05, 4 PIN |

| 文件頁(yè)數(shù): | 3/6頁(yè) |

| 文件大小: | 164K |

| 代理商: | MPX2700AP |

3

Motorola Sensor Device Data

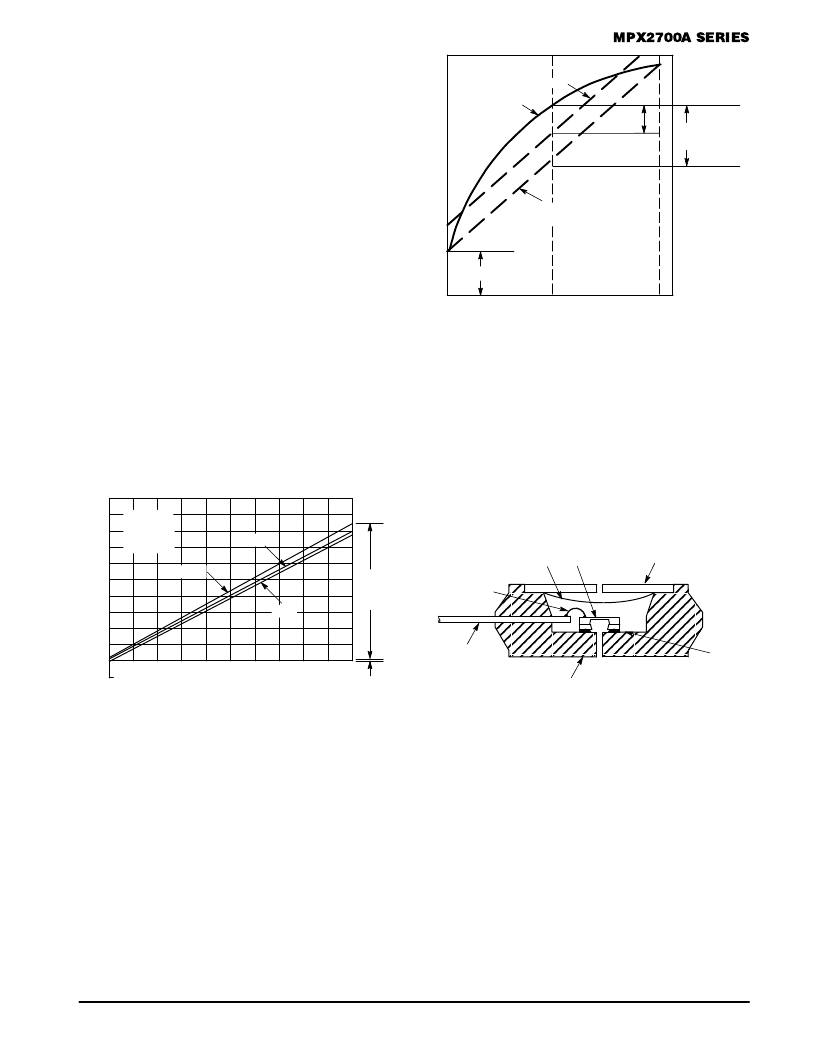

LINEARITY

Linearity refers to how well a transducer’s output follows

the equation: Vout = Voff + sensitivity x P over the operating

pressure range. There are two basic methods for calculating

nonlinearity: (1) end point straight line fit or (2) a least

squares best line fit (see Figure 3). While a least squares fit

gives the “best case” linearity error (lower numerical value),

the calculations required are burdensome.

Conversely, an end point fit will give the “worst case” error

(often more desirable in error budget calculations) and the

calculations are more straightforward for the user. Motorola’s

specified pressure sensor linearities are based on the end

point straight line method measured at the midrange

pressure.

Figure 2. Linearity Specification Comparison

LEAST

SQUARE

DEVIATION

R

PRESSURE (% FULLSCALE)

0

50

100

END POINT

STRAIGHT LINE FIT

EXAGGERATED

PERFORMANCE

CURVE

LEAST SQUARES FIT

STRAIGHT LINE

DEVIATION

OFFSET

ON–CHIP TEMPERATURE COMPENSATION and CALIBRATION

Figure 3 shows the output characteristics of the

MPX2700A series at 25

°

C. The output is directly proportional

to the differential pressure and is essentially a straight line.

The effects of temperature on Full–Scale Span and Offset

are very small and are shown under Operating Characteris-

tics.

Figure 3. Output versus Pressure Differential

Figure 4. Cross–Section of Differential Pressure

Sensor Die in Its Basic Package (Not to Scale)

ééééééééééé

SILICONE

DIE COAT

DIE

ééééééééééé

ééééééééééé

ééééééééééé

ééééééééééé

ééééééééééé

ééééééééééé

THERMOPLASTIC CASE

WIRE BOND

LEAD

FRAME

METAL COVER

RTV DIE

BOND

P2

50

40

30

20

10

–5

20

140

40

280

60

420

100

700

O

SPAN

RANGE

(TYP)

OFFSET

PSI

kPa

VS = 10 V

TA = 25

°

C

P1 > P2

MAX

TYP

MIN

0

80

560

Figure 4 shows the cross section of the Motorola MPX

pressure sensor die in the chip carrier package. A silicone

gel isolates the die surface and wire bonds from harsh

environments, while allowing the pressure signal to be

transmitted to the silicon diaphragm. MPX2700A series

pressure sensor operating characteristics and internal reli-

ability and qualification tests are based on use of dry air as

the pressure media. Media other than dry air may have

adverse effects on sensor performance and long term

reliability. Contact the factory for information regarding media

compatibility in your application.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MPX2700A | X-ducer SILICON PRESSURE SENSORS |

| MPX2700ASX | SWITCH LT 6MM 260GF 7MM HEIGHT |

| MPX2700D | 0 to 700 kPa (0 to 100 psi) 40 mV FULL SCALE SPAN (TYPICAL) |

| MPX2700GVP | 0 to 700 kPa (0 to 100 psi) 40 mV FULL SCALE SPAN (TYPICAL) |

| MPX2700GVS | 0 to 700 kPa (0 to 100 psi) 40 mV FULL SCALE SPAN (TYPICAL) |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MPX2700ASX | 制造商:MOTOROLA 制造商全稱(chēng):Motorola, Inc 功能描述:X-ducer SILICON PRESSURE SENSORS |

| MPX2700D | 制造商:MOTOROLA 制造商全稱(chēng):Motorola, Inc 功能描述:0 to 700 kPa (0 to 100 psi) 40 mV FULL SCALE SPAN (TYPICAL) |

| MPX2700DP | 制造商:MOTOROLA 制造商全稱(chēng):Motorola, Inc 功能描述:0 to 700 kPa (0 to 100 psi) 40 mV FULL SCALE SPAN (TYPICAL) |

| MPX2700GP | 制造商:MOTOROLA 制造商全稱(chēng):Motorola, Inc 功能描述:0 to 700 kPa (0 to 100 psi) 40 mV FULL SCALE SPAN (TYPICAL) |

| MPX2700GS | 制造商:MOTOROLA 制造商全稱(chēng):Motorola, Inc 功能描述:0 to 700 kPa (0 to 100 psi) 40 mV FULL SCALE SPAN (TYPICAL) |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。