- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄371122 > MMBT1010LT1 (MOTOROLA INC) PNP GENERAL PURPOSE DRIVER TRANSISTORS SURFACE MOUNT PDF資料下載

參數(shù)資料

| 型號(hào): | MMBT1010LT1 |

| 廠商: | MOTOROLA INC |

| 元件分類: | 小信號(hào)晶體管 |

| 英文描述: | PNP GENERAL PURPOSE DRIVER TRANSISTORS SURFACE MOUNT |

| 中文描述: | 100 mA, 15 V, PNP, Si, SMALL SIGNAL TRANSISTOR, TO-236AB |

| 文件頁數(shù): | 3/4頁 |

| 文件大?。?/td> | 112K |

| 代理商: | MMBT1010LT1 |

3

Motorola Small–Signal Transistors, FETs and Diodes Device Data

SOLDER STENCIL GUIDELINES

Prior to placing surface mount components onto a printed

circuit board, solder paste must be applied to the pads. A

solder stencil is required to screen the optimum amount of

solder paste onto the footprint. The stencil is made of brass

or stainless steel with a typical thickness of 0.008 inches.

The stencil opening size for the surface mounted package

should be the same as the pad size on the printed circuit

board, i.e., a 1:1 registration.

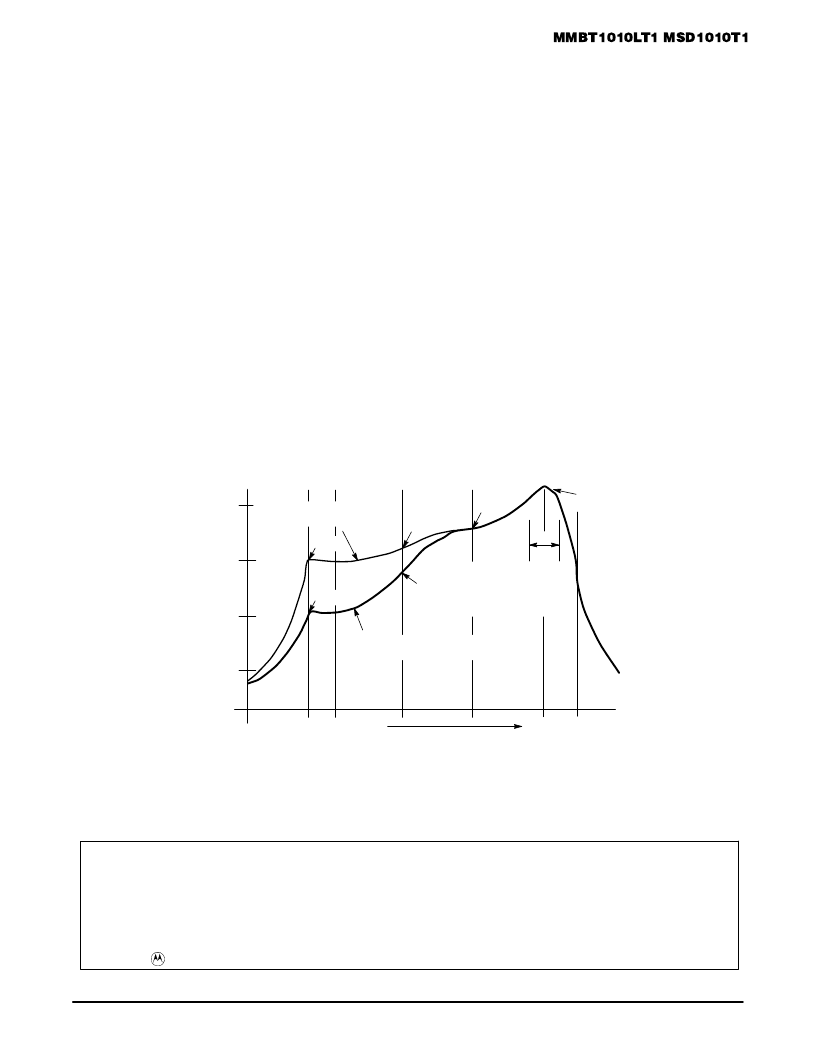

TYPICAL SOLDER HEATING PROFILE

For any given circuit board, there will be a group of control

settings that will give the desired heat pattern. The operator

must set temperatures for several heating zones, and a

figure for belt speed. Taken together, these control settings

make up a heating “profile” for that particular circuit board.

On machines controlled by a computer, the computer

remembers these profiles from one operating session to the

next. Figure 8 shows a typical heating profile for use when

soldering a surface mount device to a printed circuit board.

This profile will vary among soldering systems but it is a good

starting point. Factors that can affect the profile include the

type of soldering system in use, density and types of

components on the board, type of solder used, and the type

of board or substrate material being used. This profile shows

temperature versus time. The line on the graph shows the

actual temperature that might be experienced on the surface

of a test board at or near a central solder joint. The two

profiles are based on a high density and a low density board.

The Vitronics SMD310 convection/infrared reflow soldering

system was used to generate this profile. The type of solder

used was 62/36/2 Tin Lead Silver with a melting point

between 177–189

°

C. When this type of furnace is used for

solder reflow work, the circuit boards and solder joints tend to

heat first. The components on the board are then heated by

conduction. The circuit board, because it has a large surface

area, absorbs the thermal energy more efficiently, then

distributes this energy to the components. Because of this

effect, the main body of a component may be up to 30

degrees cooler than the adjacent solder joints.

STEP 1

PREHEAT

ZONE 1

“RAMP”

STEP 2

VENT

“SOAK”

STEP 3

HEATING

ZONES 2 & 5

“RAMP”

STEP 4

HEATING

ZONES 3 & 6

“SOAK”

STEP 5

HEATING

ZONES 4 & 7

“SPIKE”

STEP 6

VENT

STEP 7

COOLING

200

°

C

150

°

C

100

°

C

50

°

C

TIME (3 TO 7 MINUTES TOTAL)

TMAX

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

205

°

TO

219

°

C

PEAK AT

SOLDER

JOINT

DESIRED CURVE FOR LOW

MASS ASSEMBLIES

100

°

C

150

°

C

160

°

C

140

°

C

Figure 1. Typical Solder Heating Profile

DESIRED CURVE FOR HIGH

MASS ASSEMBLIES

170

°

C

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters can and do vary in different

applications. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and

are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MMBT1010T1 | PNP GENERAL PURPOSE DRIVER TRANSISTORS SURFACE MOUNT |

| MMBT1010LT1 | PNP GENERAL PURPOSE DRIVER TRANSISTORS SURFACE MOUNT |

| MMBT1010LT1 | Low Saturation Voltage |

| MMBT2222ALT1 | General Purpose Transistors |

| MMBT2222AT | NPN SMALL SIGNAL SURFACE MOUNT TRANSISTOR |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MMBT1010T1 | 制造商:ONSEMI 制造商全稱:ON Semiconductor 功能描述:PNP GENERAL PURPOSE DRIVER TRANSISTORS SURFACE MOUNT |

| MMBT1015 | 制造商:UTC-IC 制造商全稱:UTC-IC 功能描述:LOW FREQUENCY PNP AMPLIFIER TRANSISTOR |

| MMBT1015_11 | 制造商:UTC-IC 制造商全稱:UTC-IC 功能描述:LOW FREQUENCY PNP AMPLIFIER TRANSISTOR |

| MMBT1015-BL-AC3-R | 制造商:UTC-IC 制造商全稱:UTC-IC 功能描述:LOW FREQUENCY PNP AMPLIFIER TRANSISTOR |

| MMBT1015-BL-AE3-R | 制造商:UTC-IC 制造商全稱:UTC-IC 功能描述:LOW FREQUENCY PNP AMPLIFIER TRANSISTOR |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。