- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄374455 > MKT050104M500T (Sharma Electro Components Inc.) FILM CAPACITORS PDF資料下載

參數(shù)資料

| 型號: | MKT050104M500T |

| 廠商: | Sharma Electro Components Inc. |

| 英文描述: | FILM CAPACITORS |

| 中文描述: | 薄膜電容器 |

| 文件頁數(shù): | 3/29頁 |

| 文件大小: | 1151K |

| 代理商: | MKT050104M500T |

第1頁第2頁當前第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁

ELECTRICAL - BASIC PARAMETERS

1.1 RATED CAPACITANCE

The nominal or rated value of capacitance is measured at 25 °C in an measuring bridge with 1K Hz

source, free of harmonics. Please refer to relevant series for the range of capacitance value covered.

Capacitance is frequency and temperature dependent. The variation pattern of capacitance with

temperature and frequency is explained in sections 2.1 and 2.2.

1.2 CAPACITANCE TOLERANCE

The permitted variation of actual value from the nominal value is termed the tolerance. The tolerance

is expressed in percentage. The standard tolerances for plastic film capacitors are ±5% (J), ±10% (K)

and ±20% (M).

1.3 RATED VOLTAGE

The voltage at which the capacitor can operate continuously up to a temperature of 85 °C (unless

otherwise specified) is the rated voltage. As this is a critical parameter for choosing a capacitor, the

case sizes are listed in a matrix of capacitance value and rated voltage.

1.4 CATEGORY VOLTAGE

The maximum voltage that may be applied continuously over the temperature range is termed the

category voltage. This is same as the rated voltage up to 85 °C unless otherwise specified in the

climactic category of the product. Above 85 °C a derating has to be applied depending upon the

dielectric.

1.5 OPERATING TEMPERATURE

This is the temperature range with in which the capacitor can function as specified in the climactic

category. Please refer to relevant sections for derating above the temperature at which the full rated

voltage can be applied.

1.6 DISSIPATION FACTOR

This is the measurement of tangent of loss angle (tan d) and is expressed as a percentage.

Measurement of dissipation factor is carried out at 1 K Hz. or 10 K Hz. as specified in the data sheet

of the relevant series at 25 °C. Dissipation factor is temperature and frequency dependent. The

nature of variation of dissipation factor with temperature and frequency for different dielectric are

explained in Figures 2.3A to 2.3C and 2.4A to 2.4C.

1.7 INSULATION RESISTANCE

Insulation Resistance is the electrical resistance offered by the capacitor. The Insulation Resistance

is measured directly in Mega Ohms where as for higher capacitance values it is expressed in seconds

as the product of M Ohm and μF.

1.8 PULSE RISE TIME

The pulse rise time or dv/dt rating is the capability of the capacitor to handle rapid changes in voltage

or pulse. This is expressed in terms of Volts per μseconds. The dv/ dt rating of a capacitor depends

upon the dielectric as well as the design and construction of the capacitors. The dv/dt values of

different types of capacitors are listed in the corresponding data sheets of the capacitors.

ELECTRICAL - EFFECTS AND RELATIONS

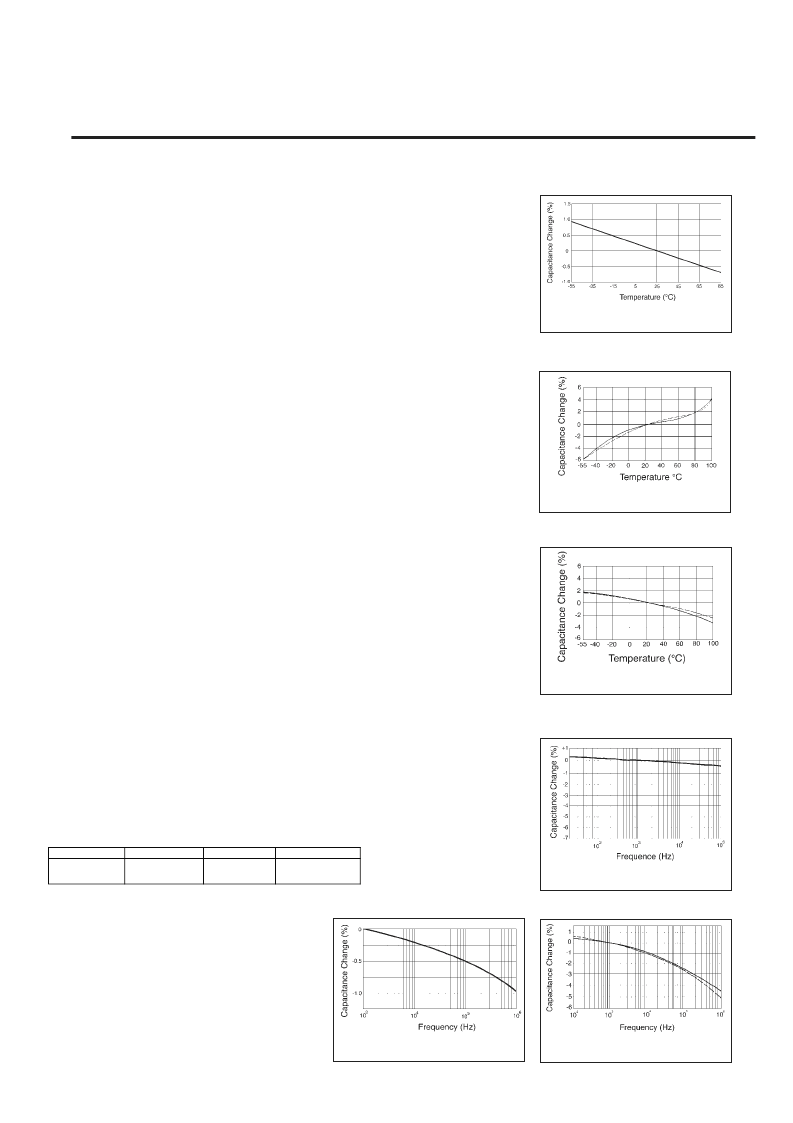

2.1 TEMPERATURE DEPENDENCE OF CAPACITANCE

Capacitance of plastic film capacitors vary with temperature. However the pattern of variation is

different for different plastic film dielectrics such as Polystyrene, Polyester and Polypropylene. The

The variation patterns for these dielectrics are shown in figure 2.1A, 2.1B and 2.1C. The rate of

change of capacitance with temperature is termed the Temperature Coefficient. The nominal values

of temperature coefficient for different dielectrics are shown below.

2.2 FREQUENCY DEPENDENCE OF CAPACITANCE

Capacitance reduces with increase in frequency. The

variation pattern for different dielectrics are shown in

figure 2.2A, 2.2B and 2.2C.

2.3 TEMPERATURE DEPENDENCE OF

DISSIPATION FACTOR

The dissipation factor varies with temperature. Each

dielectric follows a unique variation pattern. The variation

pattern for different dielectrics are shown in figure 2.3A,

2.3B and 2.3C.

PERFORMANCE CHARACTERISTICS

Figure 2.1B

Figure 2.1C

Figure 2.2A

Figure 2.2C

Figure 2.2B

Polyester

Capacitance Change Vs. Temperature

Polypropylene

Capacitance Change Vs. Temperature

Polystyrene

Capacitance Change Vs. Frequency

Polyester

Capacitance Change Vs. Frequency

Polypropylene

Capacitance Change Vs. Frequency

DIELECTRICS

POLYSTYRENE

POLYESTER

POLYPROPYLENE

TEMPERATURE

COEFFICIENT

-150 ppm

+400 ppm

-200 ppm

Figure 2.1A

Polystyrene

Capacitance Change Vs. Temperature

Sharma Film Capacitors

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| MKT075102A101 | FILM CAPACITORS |

| MKT075102A101A | FILM CAPACITORS |

| MKT075102A101T | FILM CAPACITORS |

| MKT075102A251 | FILM CAPACITORS |

| MKT075102A251A | FILM CAPACITORS |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| MKT075 | 制造商:SHARMA 制造商全稱:Sharma Electro Components,Inc 功能描述:Sharma Film Capacitors |

| MKT075_1 | 制造商:SHARMA 制造商全稱:Sharma Electro Components,Inc 功能描述:Sharma Film Capacitors |

| MKT075102A101 | 制造商:SHARMA 制造商全稱:Sharma Electro Components,Inc 功能描述:FILM CAPACITORS |

| MKT075102A101A | 制造商:SHARMA 制造商全稱:Sharma Electro Components,Inc 功能描述:FILM CAPACITORS |

| MKT075102A101T | 制造商:SHARMA 制造商全稱:Sharma Electro Components,Inc 功能描述:FILM CAPACITORS |

發(fā)布緊急采購,3分鐘左右您將得到回復。