- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄385394 > HSDL-9001 (Avago Technologies Ltd.) Miniature Surface-Mount Ambient Light Photo Diode PDF資料下載

參數(shù)資料

| 型號: | HSDL-9001 |

| 廠商: | Avago Technologies Ltd. |

| 英文描述: | Miniature Surface-Mount Ambient Light Photo Diode |

| 中文描述: | 微型表面貼裝環(huán)境光光電二極管 |

| 文件頁數(shù): | 7/12頁 |

| 文件大小: | 106K |

| 代理商: | HSDL-9001 |

7

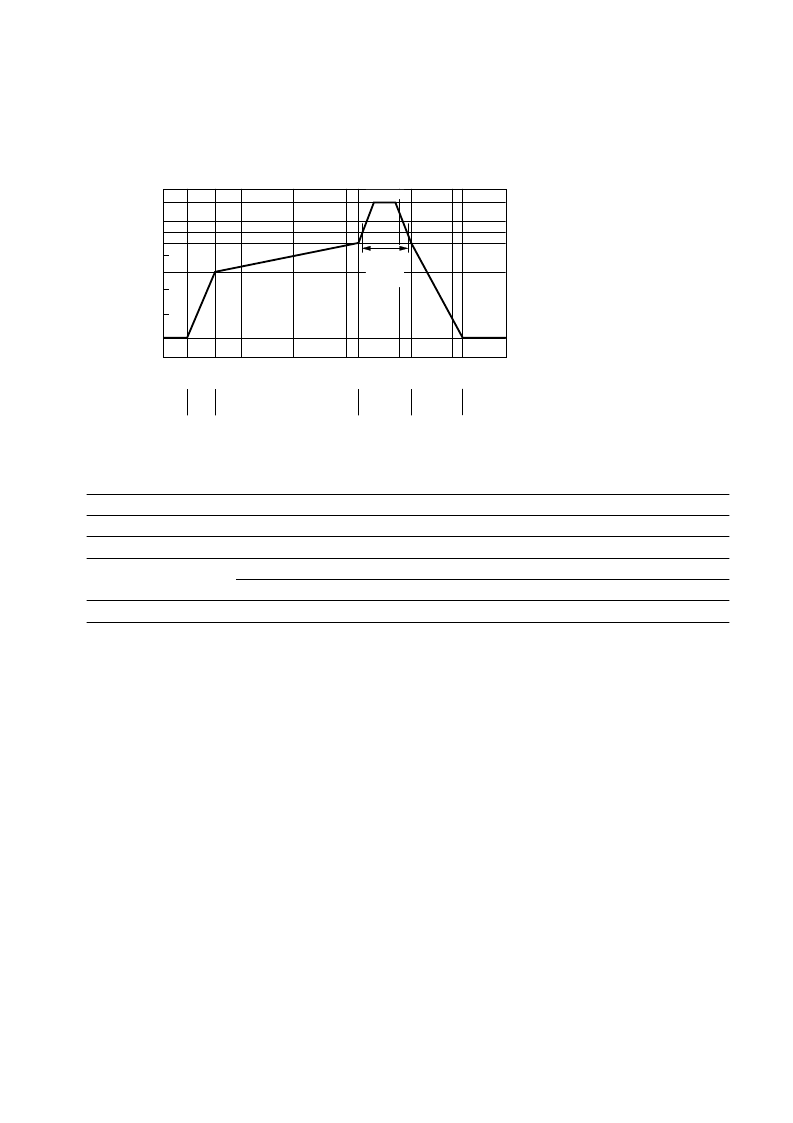

Figure 6. Reflow graph.

Reflow Profile

The reflow profile is a straight-

line representation of a nominal

temperature profile for a con-

vective reflow solder process.

The temperature profile is divided

into four process zones, each

with different

T/

time tempera-

ture change rates. The

T/

time

rates detailed in the above table.

The temperatures are measured

at the component to printed

circuit board connections.

In

process zone P1

, the PC

board and I/O pins are heated to

a temperature of 160

°

C to

activate the flux in the solder

paste. The temperature ramp up

rate, R1, is limited to 4

°

C per

second to allow for even heating

of both the PC board and HSDL-

9001 I/O pins.

Process

Heat Up

Solder Paste Dry

Solder Reflow

Symbol

P1, R1

P2, R2

P3, R3

P3, R4

P4, R5

T

25

°

C to 160

°

C

160

°

C to 200

°

C

200

°

C to 255

°

C (260

°

C at 10 seconds max.)

255

°

C to 200

°

C

200

°

C to 25

°

C

Maximum

T/

time

4

°

C/s

0.5

°

C/s

4

°

C/s

–6

°

C/s

–6

°

C/s

Cool Down

Process zone P2

should be of

sufficient time duration (60 to

–120 seconds) to dry the solder

paste. The temperature is raised

to a level just below the liquidus

point of the solder, usually

200

°

C (392

°

F).

Process zone P3

is the solder

reflow zone. In zone P3, the

temperature is quickly raised

above the liquidus point of solder

to 255

°

C (491

°

F) for optimum

results. The dwell time above the

liquidus point of solder should be

between 20 and 60 seconds. It

usually takes about 20 seconds to

assure proper coalescence of the

solder balls into liquid solder and

the formation of good solder

connections. Beyond a dwell time

of 60 seconds, the intermetallic

growth within the solder

connections becomes excessive,

resulting in the formation of weak

and unreliable connections. The

temperature is then rapidly

reduced to a point below the

solidus temperature of the solder,

usually 200

°

C (392

°

F), to allow

the solder within the connections

to freeze solid.

Process zone P4

is the cool down

after solder freeze. The cool down

rate, R5, from the liquidus point of

the solder to 25

°

C (77

°

F) should

not exceed –6

°

C per second

maximum. This limitation is

necessary to allow the PC board

and transceiver’s castellation I/O

pins to change dimensions evenly,

putting minimal stresses on the

HSDL-9001.

0

t-TIME (SECONDS)

T

°

C

230

220

200

180

160

120

80

50

150

100

200

250

300

255

P1

HEAT

UP

P2

SOLDER PASTE DRY

P3

SOLDER

REFLOW

P4

COOL

DOWN

25

R1

R2

R3

R4

R5

60 sec.

MAX.

ABOVE

217

°

C

MAX. 260

°

C

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HSDL-9100 | Surface-Mount Proximity Sensor |

| HSDL-9100-001 | Surface-Mount Proximity Sensor |

| HSDL-9100-021 | Surface-Mount Proximity Sensor |

| HSH1205D | DC/DC CONVERTERS 12 VOLT INPUT |

| HSMA-A400-T35M1 | SMT LED Surface Mount LED Indicator |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HSDL-9100 | 制造商:Avago Technologies 功能描述:Bulk |

| HSDL-9100_09 | 制造商:AVAGO 制造商全稱:AVAGO TECHNOLOGIES LIMITED 功能描述:Surface-Mount Proximity Sensor |

| HSDL-9100-001 | 制造商:Avago Technologies 功能描述: |

| HSDL-9100-021 | 功能描述:板機(jī)接口移動感應(yīng)器和位置傳感器 Proximity Sensor RoHS:否 制造商:Panasonic Electric Works 封裝 / 箱體:TO-5 感應(yīng)距離:3 m 輸出類型:Digital 電源電壓-最大:6 V 電源電壓-最小:2.3 V 電源電流: 最大工作溫度:+ 60 C 封裝:Bulk |

| HSDL-9100-024 | 功能描述:近程傳感器 Proximity Sensor RoHS:否 制造商:Vishay Semiconductors 感應(yīng)方式:Optical 感應(yīng)距離:1 mm to 200 mm 電源電壓:2.5 V to 3.6 V 安裝風(fēng)格:SMD/SMT 輸出配置:Digital 最大工作溫度:+ 85 C 最小工作溫度:- 25 C 系列:VCNL3020 |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。