- 您現(xiàn)在的位置:買賣IC網(wǎng) > Datasheet目錄61 > HMU-PJAT1K-A20R1 (Hirose Electric Co Ltd)CONN MU ATTENUATOR FIXED 20DB Datasheet資料下載

參數(shù)資料

| 型號: | HMU-PJAT1K-A20R1 |

| 廠商: | Hirose Electric Co Ltd |

| 文件頁數(shù): | 2/3頁 |

| 文件大?。?/td> | 197K |

| 描述: | CONN MU ATTENUATOR FIXED 20DB |

| 標(biāo)準(zhǔn)包裝: | 20 |

| 系列: | HMU |

| 類型: | MU |

| 衰減值: | 20dB |

| 其它名稱: | *HMU-PJAT1K-A20R1 |

89

MU-PJ Type Optical Fixed Attenuators

?SPAN class="pst HMU-PJAT1K-A20R1_2612104_4">Product Specifcations

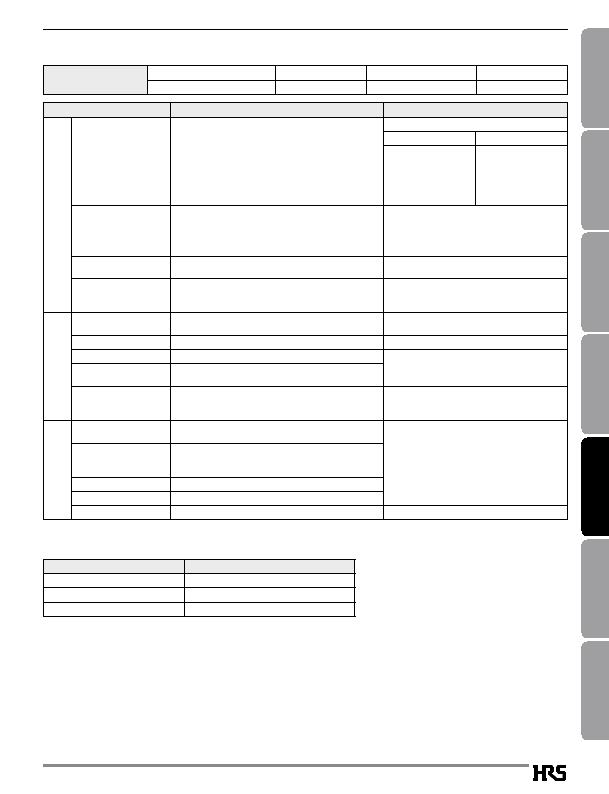

Ratings

Operating temperature range

-25癈 to +70癈

Storage temperature range

-40癈 to +85癈

Max. Input Power

200 mW

Fiber type

SM

Item

Test Method

Specifications

Attenuation

Wavelength : 1510 to 1620nm

1310 ?0nm

Operating temperature

-10?to +60?/DIV>

-25?to +75?/DIV>

0

+0.4dB

1,2

?.5dB

3,4,5

?.8dB

6,7,8,9,10

?.0dB

15

?.5dB

20

?.0dB

0

+0.4dB

1,2

?.7dB

3,4,5

?.0dB

6,7,8,9,10

?.2dB

15

?.7dB

20

?.2dB

Attenuation deviation

(Wavelength dependance)

Difference between max and min attenuation value at the

wavelength range of 1510 to 1620 nm and 1310 ?0nm

0dB

: 0.4dB max.

1,2,3,4,5dB : 0.5dB max.

6,7,8,9,10dB : 0.75dB max.

15dB

: 1.0dB max.

20dB

: 1.5dB max.

Return Loss

Measurement at a point within wavelength 1310 ?0nm

and a point within wavelength 1550 ?0nm

e40 dB min.

Power test

Power : 200mW

Time : 100 hours

Laser : LD (Wavelength : 1470nm)

Attenuation and return loss

shall be satisfied before, during and after

the test.

Engagement and

separation forces

Engagement and separation forces at 50mm/s

Engagement force : d 20 N

Separation force

: d 20 N

Gauge retention force

Zirconia gauge at ?1.249 ?.0005mm

1.0 N to 2.5 N

Mating durability

Insertion and extraction number : 500

1) Insertion loss fluctuation after test: 0.2dB max.

2) No visible damage, cracks or part dislocation.

Impact test

5 times in each of three mutually perpendicular axis with

the accelertion 981 m/s

2

. (Total : 30 times)

Vibration

3 hours at an amplitude of 1.5mm with the frequency

range 10 to 55 Hz in each of three mutually perpendicular

plane

1) Attenuation and return loss shall be satisfied

before, during and after the test.

2) No breakage, crack or looseness on components.

Composite temperature

-humidity cyclic tast

Humidity : 90 to 96%, Temperature : -10 to 65癈,

Time : 480 hours (20 cycles)

1) Attenuation and return loss shall be satisfied

before and after the test.

2) No breakage, crack or looseness on components.

Change of tempreature

Temperature: -40?to +80?

Time: 400 hours(100 cycles)

Dry heat

Tempreature : 85癈, Time : 500 hours

Cold

Tempreature : -40癈, Time : 500 hours

Salt mist

Salt mist : 5%, Time : 48 hours

No corrosion.

?SPAN class="pst HMU-PJAT1K-A20R1_2612104_4">Materials

Part

Material

Body

Zinc alloy

Ferrule

Zirconia

Split sleeve

Zirconia

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| HOA1870-033 | SENSOR INFRARED |

| HOA1873-013 | SENSOR PHOTODARLINGTON NPN SLOT |

| HOA1874-011 | SNSR OPTO TRANS 3.05MM TRANSM |

| HOA1877-002 | SENSOR PHOTOTRANS NPN SLOTTED |

| HOA1881-013 | SENSOR PHOTOTRANS SLOT OPTICAL |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| HMU-PJAT1K-A20R1(20) | 功能描述:衰減器 -互連 MU ATTEN FIXED 20DB RoHS:否 制造商:Pomona Electronics 最大衰減: 容差: 頻率范圍:DC to 500 MHz 阻抗:50 Ohms 功率額定值:2 W 端接類型:Crimp 連接器類型:BNC Male / Female 工作溫度范圍:0 C to + 102 C |

| HMW44115 | 制造商:Hubbell Wiring Device-Kellems 功能描述:MiniPort, 4PORT, HW, 4 WIRE, WITH LED |

| HMW48215 | 制造商:Hubbell Wiring Device-Kellems 功能描述:MINIPORT, 8-P, HARD WIRED, 4W |

| HMX1225 | 制造商:HSMC 制造商全稱:HSMC 功能描述:0.8A 300/380 VOLTAGE SCRS IGT<200uA |

| HMX2000 | 制造商:HONEYWELL 制造商全稱:Honeywell Solid State Electronics Center 功能描述:MIXED SIGNAL SOI GATE ARRAYS |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。