- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄357857 > G6WK-1P-24VDC RF RELAY, SPDT, LATCHED, 0.015A (COIL), 24VDC (COIL), 360mW (COIL), 0.5A (CONTACT), 30VDC (CONTACT), 2500MHz, THROUGH HOLE-STRAIGHT MOUNT PDF資料下載

參數(shù)資料

| 型號: | G6WK-1P-24VDC |

| 元件分類: | 射頻繼電器 |

| 英文描述: | RF RELAY, SPDT, LATCHED, 0.015A (COIL), 24VDC (COIL), 360mW (COIL), 0.5A (CONTACT), 30VDC (CONTACT), 2500MHz, THROUGH HOLE-STRAIGHT MOUNT |

| 文件頁數(shù): | 8/8頁 |

| 文件大?。?/td> | 375K |

| 代理商: | G6WK-1P-24VDC |

G6W

G6W

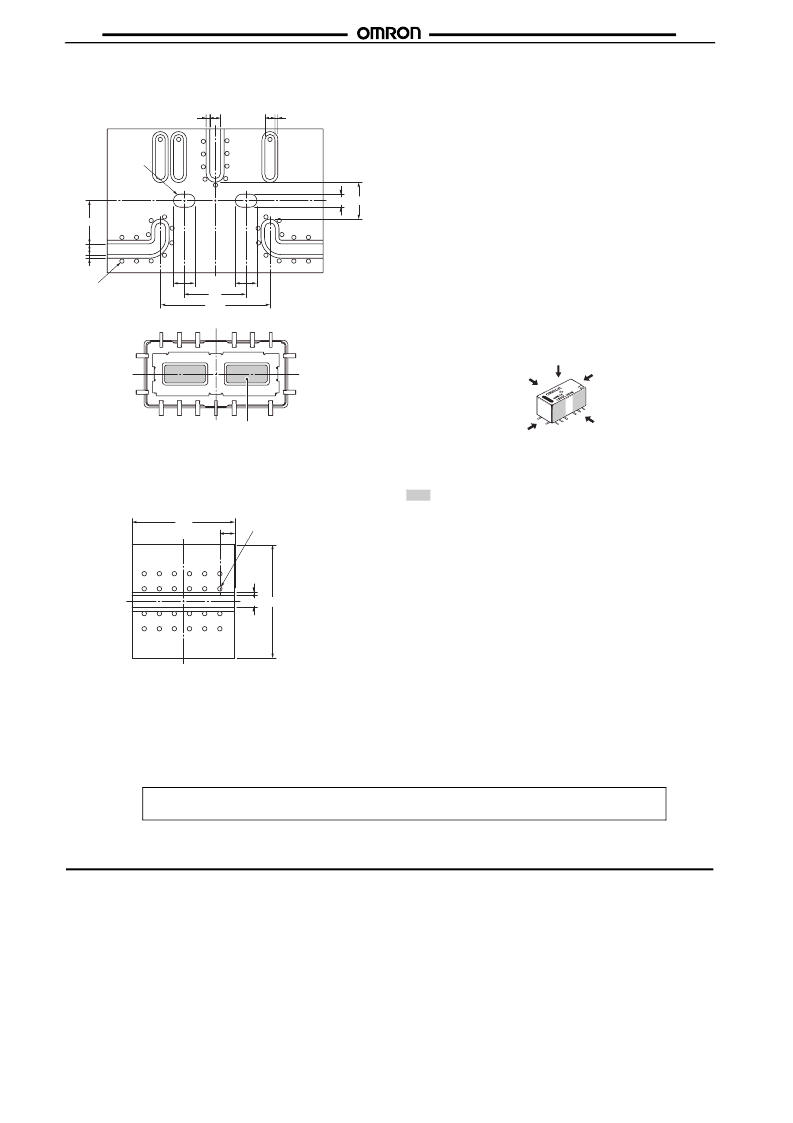

SMD-type substrate

Substrate: t-0.8 BT resin (Dielectric constant at 2 GHz: 3.37)

Note:

To obtain high-frequency characteristics close to the

charts shown on page 2, solder the convex point on the

undersurface of the relay to the ground pattern of the

substrate.

Base plate for high-frequency characteristic compensation

Note:

The above compensation plate is used to measure the

loss by the relay.

The relay loss is determined by subtracting the data

measured for a compensation base plate from those for a

high-frequency characteristics measuring substrate

mounted with a relay.

Handling

Leave the Relays packed until just prior to mounting them.

Dropping the relay may cause damage to its functional capability.

Never use the relay if it is dropped.

Protect the relays from direct sunlight during operation, storage,

and transportation and keep the relays under normal temperature,

humidity, and pressure.

Soldering

Solder: JIS Z3282, H63A

Soldering temperature: Approx. 250

°

C (At 260

°

C if the DWS

method is used.)

Soldering time: Approx. 5 s max. (approx. 2 s for the first time and

approx. 3 s for the second time if the DWS method is used.)

Be sure to adjust the level of the molten solder so that the solder

will not overflow onto the PCB.

Claw Securing Force During Automatic Insertion

During automatic insertion of Relays, make sure to set the

securing force of the claws to the following values so that the

Relay characteristics will be maintained.

Latching Relay Mounting

Make sure that the vibration or shock that is generated from other

devices, such as relays in operation, on the same panel and

imposed on the Latching Relay does not exceed the rated value,

otherwise the Latching Relay that has been set may be reset or

vice versa. The Latching Relay is reset before shipping. If

excessive vibration or shock is imposed, however, the Latching

Relay may be set accidentally. Be sure to apply a reset signal

before use.

Coating

Relays mounted on PCBs may be coated or washed. Do not

apply silicone coating or detergent containing silicone, otherwise

the silicone coating or detergent may remain on the surface of the

Relays.

Convex position

15.24

5.12

1.8

1.5

0.5

1.4

0.4

8.6

3

Thirty one, 0.6-dia.,

through-hole

1.5

6

0.5

3

Undersurface of relay

Through-

hole

15

0.5

13.6

1.5

2

Twenty four, 0.6-dia.,

through-hole

Secure the claws to the area indicated by shading.

Do not attach them to the center area or to only part of the

Relay.

A

C

B

Direction A: 4.90 N max.

Direction B: 9.80 N max.

Direction C: 9.80 N max.

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Electronic Components Company

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. K120-E1-01

Electronic & Mechanical Components Division H.Q.

Low Signal Relay Division

2-1, 2-Chome, Nishikusatsu, Kusatsu-City,

Shiga, 525-0035 Japan

Tel: (81)77-565-5481/Fax: (81)77-565-5581

Printed in Japan

0702-2M (0702) (B)

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| G8198-02 | PIN PHOTO DIODE |

| G8JN-1C6T-DC12 | POWER/SIGNAL RELAY, SPDT, MOMENTARY, 0.16A (COIL), 12VDC (COIL), 1920mW (COIL), 35A (CONTACT), 16VDC (CONTACT), PANEL MOUNT |

| G8JN-1C6T-F-DC12 | POWER/SIGNAL RELAY, SPDT, MOMENTARY, 0.16A (COIL), 12VDC (COIL), 1920mW (COIL), 35A (CONTACT), 16VDC (CONTACT), PANEL MOUNT |

| G8JN-1C6T-F-R-DC12 | POWER/SIGNAL RELAY, SPDT, MOMENTARY, 0.16A (COIL), 12VDC (COIL), 1920mW (COIL), 35A (CONTACT), 16VDC (CONTACT), PANEL MOUNT |

| G8JN-1C6T-R-DC12 | POWER/SIGNAL RELAY, SPDT, MOMENTARY, 0.16A (COIL), 12VDC (COIL), 1920mW (COIL), 35A (CONTACT), 16VDC (CONTACT), PANEL MOUNT |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| G6WK1PDC12 | 制造商:Omron Electronic Components LLC 功能描述:RELAY RF SPDT 10MA 12V |

| G6WK1PDC24 | 制造商:Omron Electronic Components LLC 功能描述:RELAY RF SPDT 10MA 24V |

| G6WK1PDC3 | 制造商:Omron Electronic Components LLC 功能描述:RELAY RF SPDT 10MA 3V |

| G6WK-1P-DC4.5 | 功能描述:高頻/射頻繼電器 5 GHZ SPDT 4.5VDC FREQ RoHS:否 制造商:Omron Electronics 觸點形式:2 Form C (DPDT-BM) 觸點電流額定值: 線圈電壓:5 VDC 線圈類型:Non-Latching 頻率: 功耗:100 mW 端接類型:Solder Terminal 絕緣:20 dB to 30 dB at 1 GHz 介入損耗:0.2 dB at 1 GHz |

| G6WK1PDC45 | 制造商:Omron Electronic Components LLC 功能描述:RELAY RF SPDT 10MA 4.5V |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。