- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄357604 > ASOF5S3E-10.00MHZ (CONNOR WINFIELD CORP) OCXO, CLOCK, 10 MHz, HCMOS OUTPUT PDF資料下載

參數(shù)資料

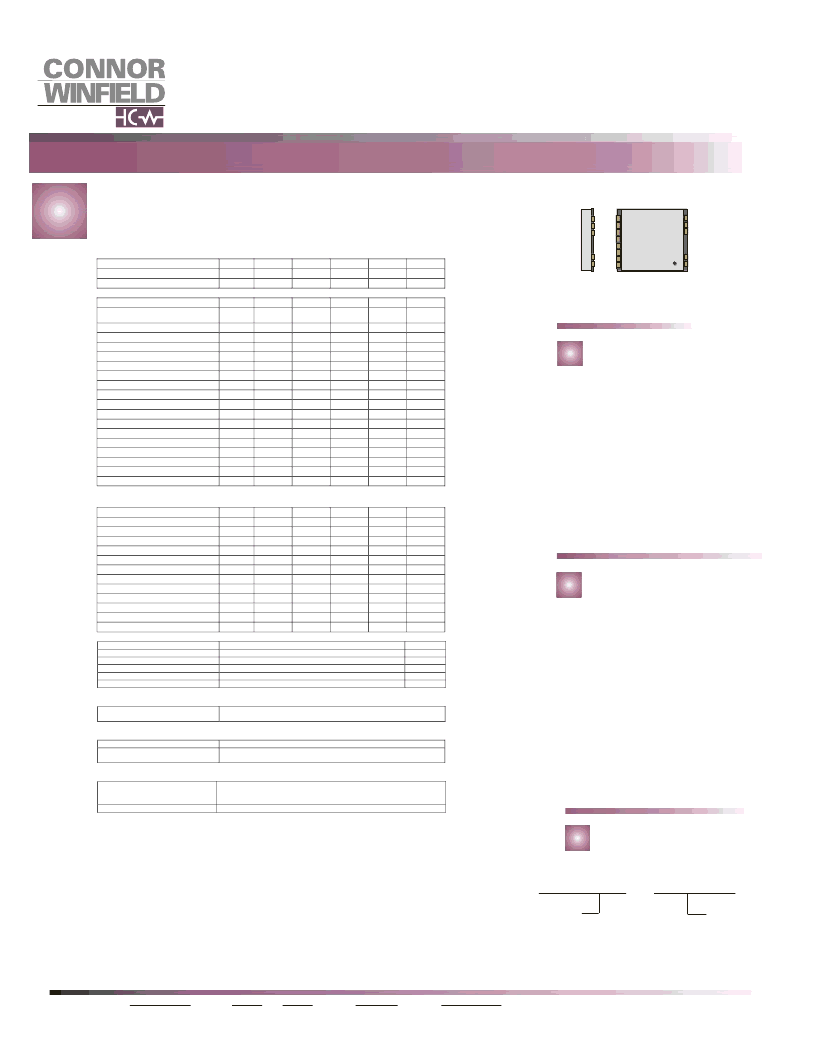

| 型號: | ASOF5S3E-10.00MHZ |

| 廠商: | CONNOR WINFIELD CORP |

| 元件分類: | XO, clock |

| 英文描述: | OCXO, CLOCK, 10 MHz, HCMOS OUTPUT |

| 封裝: | SURFACE MOUNT PACKAGE-16 |

| 文件頁數(shù): | 1/2頁 |

| 文件大小: | 201K |

| 代理商: | ASOF5S3E-10.00MHZ |

THE CONNOR-WINFIELD CORP.

2111 COMPREHENSIVE DRIVE.

AURORA, IL 60505.

FAX (630) 851-5040.

PHONE (630) 851-4722.

www.conwin.com

P R O D UC T D ATA S HE E T

Specifications subject to change without notice.

Copyright 2001 Connor-Winfield all rights reserved.

DATA SHEET #:

REV:

DATE:

PAGE

OF

a

CRYSTAL CONTROLLED OSCILLATORS

1

2

Cx024

02

9/19/03

The Connor-Winfield

ASOF5S3E is a 5V Surface

Mount Oven Controlled

Crystal Oscillator (OCXO)

with an HCMOS output. The

ASOF5S3E is designed for

Stratum 3E applications

requiring low jitter and tight

frequency stability.

ASOF5S3E - 10.00MHz

OCXO

SERIES

CENTER

FREQUENCY

FEATURES

DESCRIPTION

ORDERING INFORMATION

SURFACE MOUNT PACKAGE

FIXED FREQUENCY OCXO

DESIGNED TO MEET STRATUM 3E

REQUIREMENTS

FREQUENCY STABILITY ±10ppb

5.0V OPERATION

HCMOS OUTPUT

TAPE AND REEL PACKAGING

SURFACE MOUNT STRATUM 3E HCMOS OCXO

ASOF5S3E

Notes:

1) Labels will include the calibration frequency at the time of ship.

2) Initial calibration @ 25

°

C

3) Overall Frequency Stability, 0° to 70°C

4) After ten days of continuous operation.

5) Allen Variance: 1 second, 100 average.

6) Frequency vs. change in supply voltage.

7) Frequency vs. change in load.

8) Vcc = 5.0Vdc.

9) From Vcc=90% of final value. No more than 16 transitions at start-up before oscillator

has started.

10) Measured @ 0

°

C, within 5 minutes, referenced one hour after turn-on.

11) At time of delivery.

12) HCMOS load.

13) For a given off time, the time required to meet daily aging, short-term stability and TDEV

requirements.

C

A

1

ABSOLUTE MAXIMUM RATINGS

PARAMETER

Storage Temperature

Supply Voltage

OPERATING SPECIFICATIONS

PARAMETER

TABLE 1.0

NOTE

TABLE 2.0

NOTE

1

UNITS

(Vcc)

MINIMUM

-40

-0.5

NOMINAL MAXIMUM

-

-

NOMINAL MAXIMUM

10

12.8

-

-

-

5.00E-11

-

-

5.00

-

-

-

-

-

5

-

-

UNITS

°C

Vdc

85

7

MINIMUM

UNITS

Center Frequency

Frequency Calibration

Frequency Stability

Aging: Daily

Aging: First Year

Aging: Short Term (1Sec.)

Aging: Long Term (20 Years)

Operating Temperature Range

Supply Voltage

Frequency vs. Voltage Stability (+/-1%)

Frequency vs. Load Stability (+/-20%)

Power Consumption: Turn On

Power Consumption: Steady-State

Start-Up Time

Warm Up

2G Tip-over

TDEV at 300 seconds

TDEV at 40 seconds

HCMOS OUTPUT

CHARACTERISTICS

PARAMETER

LOAD

Voltage (High)

(Low)

Duty Cycle at 50% of Vcc

Rise / Fall Time 10% to 90%

Spurious Output

Sub-Harmonics

SSB Phase Noise at 1Hz offset

SSB Phase Noise at 10Hz offset

SSB Phase Noise at 100Hz offset

SSB Phase Noise at 1KHz offset

SSB Phase Noise at 10KHz offset

RESTABILIZATION TIME

Off Time

< 1 Hour

< 6 Hours

< 24 Hours

1 to 16 Days

> 16 Days

PACKAGE

CHARACTERISTICS

Package

(Fo)

(Vcc)

4

10

1

30

-

300

70

5.25

0.5

0.5

2.75

1. 50

500

100

-

5

1

MHz

ppm

ppb

ppb/day

ppb

RMS

ppb

°C

Vdc

ppb

ppb

W

W

mS

ppb

ppb/G

nS

nS

-4

-10

-1

-30

-

-

0

4.75

-0.5

-0.5

-

-

-100

-

-

-

2

3

4

5

6

7

8

8

9

10

11

11

TABLE 3.0

NOTE

12

MINIMUM

12

Vcc-0.2V

-

45

-

-

-

-

-

-

-

NOMINAL

15

-

-

50

-

-

-

-

-

-

-

MAXIMUM

18

-

0.2

55

5

-80

-25

-90

-115

-130

-135

-140

UNITS

pF

Vdc

Vdc

%

nS

dBc

dBc

dBc/Hz

dBc/Hz

dBc/Hz

dBc/Hz

dBc/Hz

(Voh)

(Vol)

TABLE 4.0

NOTE

13

13

13

13

13

Restabilization Time

< 2 Hours

< 12 Hours

< 48 Hours

48 Hours + Off Time

< 6 Days

TABLE 5.0

Non-hermetic package consisting of an FR4 substrate with grounded metal

cover.

ENVIRONMNETAL

CHARACTERISTICS

Shock

Vibration

TABLE 6.0

100G’s, 6mS, halfsine per MIL-STD-202F, Method 213B, Test Condition C

0.06” D.A. or 10G peak 10 to 500 Hz, per MIL-STD-202F, Method 204D,

Test condition A

PROCESS

RECOMMENDATIONS

Solder Reflow

TABLE 7.0

The component solder used internal to this device has a melting point of

221

°

C. The peak temperature inside the device should be less than or equal

to 220

°

C for a maximum of 10 seconds

Ultrasonic cleaning is not recommended.

Wash

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| ASOF5S3E-12.80MHZ | OCXO, CLOCK, 12.8 MHz, HCMOS OUTPUT |

| ASPH7450 | 220 MHz - 225 MHz MOBILE STATION ANTENNA, 5.15 dBi GAIN |

| ASTX-06-FREQ-T-OUT2 | TCXO, CLIPPED SINE OUTPUT, 12.6 MHz - 19.8 MHz |

| ASVC-0806-R80K | 1 ELEMENT, 0.8 uH, IRON-CORE, GENERAL PURPOSE INDUCTOR |

| ASVC-0806-R60J | 1 ELEMENT, 0.6 uH, IRON-CORE, GENERAL PURPOSE INDUCTOR |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| ASOV3S3 | 制造商:CONNOR-WINFIELD 制造商全稱:Connor-Winfield Corporation 功能描述:SURFACE MOUNT 3.3V HCMOS STRATUM 3 OCXO |

| ASOV3S3-12.80M | 制造商:CONNOR-WINFIELD 制造商全稱:Connor-Winfield Corporation 功能描述:SURFACE MOUNT 3.3V HCMOS STRATUM 3 OCXO |

| ASOV5S3 | 制造商:CONNOR-WINFIELD 制造商全稱:Connor-Winfield Corporation 功能描述:CRYSTAL CONTROLLED OSCILLATORS |

| ASOV5S3-12.80 | 制造商:CONNOR-WINFIELD 制造商全稱:Connor-Winfield Corporation 功能描述:CRYSTAL CONTROLLED OSCILLATORS |

| ASOV5S3E | 制造商:CONNOR-WINFIELD 制造商全稱:Connor-Winfield Corporation 功能描述:SURFACE MOUNT STRATUM 3E HCMOS VCOCXO |

發(fā)布緊急采購,3分鐘左右您將得到回復。