- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄360262 > 595D156X96R3A2T KONDENSATOR TANTAL SMD 15UF 6.3V PDF資料下載

參數(shù)資料

| 型號(hào): | 595D156X96R3A2T |

| 英文描述: | KONDENSATOR TANTAL SMD 15UF 6.3V |

| 中文描述: | KONDENSATOR鉭貼片15UF 6.3V的 |

| 文件頁(yè)數(shù): | 7/7頁(yè) |

| 文件大?。?/td> | 85K |

| 代理商: | 595D156X96R3A2T |

52

T Y PE 595D

GUIDE T O APPLICAT ION

1.

A-C Ripple Current:

The maximum allowable ripple

current shall be determined from the formula:

where,

P

= Power Dissipation in Watts @ + 25

°

C as

given in the table in Paragraph Number 5

(Power Dissipation).

R

ESR

= The capacitor Equivalent Series Resistance

at the specified frequency.

2.

A-C Ripple Voltage:

The maximum allowable ripple

voltage shall be determined from the formula:

or, from the formula:

V

rms

= I

rms

x Z

where,

P

= Power Dissipation in Watts @ + 25

°

C as

given in the table in Paragraph Number 5

(Power Dissipation).

R

ESR

= The capacitor Equivalent Series Resistance

at the specified frequency.

Z

= The capacitor Impedance at the specified

frequency.

2.1

The sum of the peak AC voltage plus the DC voltage

shall not exceed the DC voltage rating of the capacitor.

2.2

The sum of the negative peak AC voltage plus the

applied DC voltage shall not allow a voltage reversal

exceeding 10% of the DC working voltage at + 25

°

C.

3.

Reverse Voltage:

These capacitors are capable of

withstanding peak voltages in the reverse direction

equal to 10% of the DC rating at + 25

°

C and 5% of the

DC rating at + 85

°

C.

4.

Temperature Derating:

If these capacitors are to be

operated at temperatures above + 25

°

C, the

permissible rms ripple current or voltage shall be

calculated using the derating factors as shown:

P

R

ESR

I

rms

=

Z

V

rms

=

P

R

ESR

T

A

B

C

D

R

Maximum Permissible

Power Dissipation

@ + 25

°

C (Watts)

in free air

Case

Code

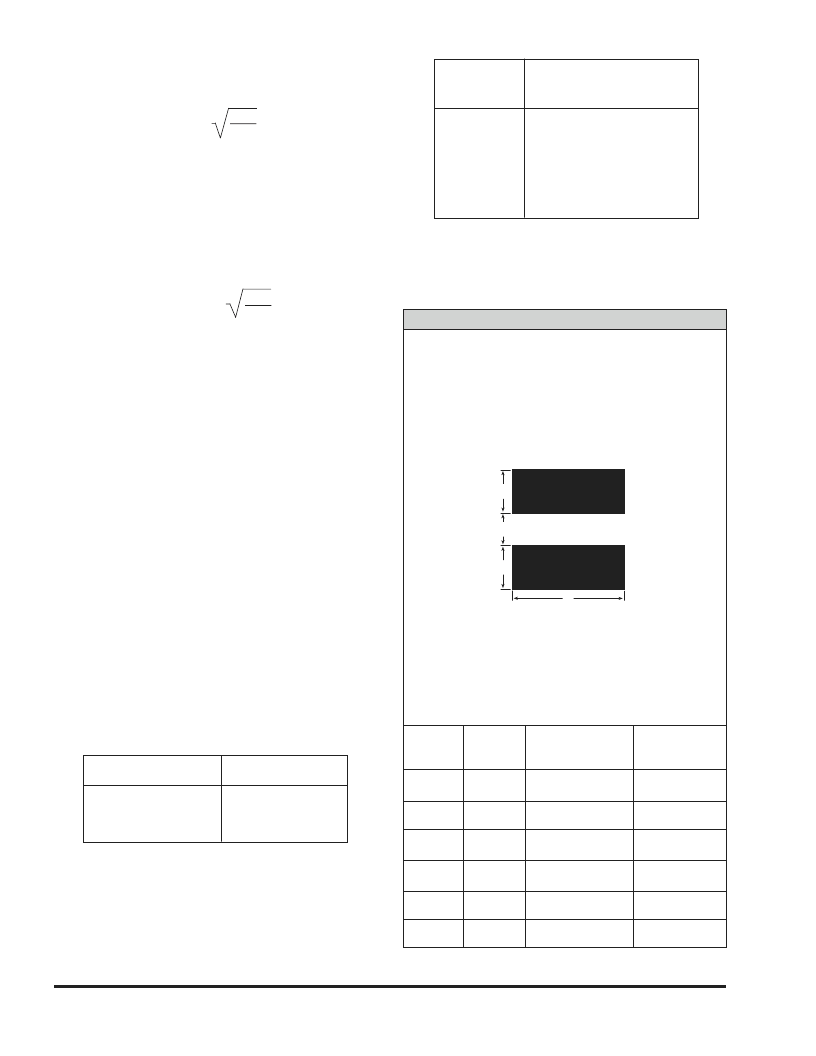

6.

Recommended Mounting Pad Geometries:

The

nib must have sufficient clearance to avoid electrical

contact with other components. The width dimension

indicated is the same as the maximum width of the

capacitor. This is to minimize lateral movement.

Derating

Factor

1.0

0.9

0.8

0.4

Temperature

+ 25

°

C

+ 55

°

C

+ 85

°

C

+ 125

°

C

5.

Power Dissipation:

Power dissipation will be

affected by the heat sinking capability of the mounting

surface. Non-sinusoidal ripple current may produce

heating effects which differ from those shown. It is

important that the equivalent Irmsvalue be

established when calculating permissible operating

levels. (Power dissipation calculated using + 25

°

C

temperature rise.)

[Numbers in brackets indicate millimeters]

* Pads for B, C and D case codes are otherwise pad compatible with

*

Type 293D, B, C and D case codes respectively.

REFLOW S OLDER PADS *

WIDTH

(A)

.055

[1.5]

.082

[2.1]

.120

[3.0]

.136

[3.5]

.180

[4.6]

.245

[6.3]

PAD

METALLIZATION

(B)

.030

[0.7]

.065

[1.7]

.065

[1.7]

.090

[2.3]

.090

[2.3]

.090

[2.3]

SEPARATION

(C)

.025

[0.6]

.050

[1.3]

.065

[1.7]

.120

[3.1]

.145

[3.7]

.145

[3.7]

CASE

CODE

T

A

B

C

D

R

A

B

B

C

0.030

0.070

0.080

0.110

0.150

0.250

Vishay Sprague

70 Pembroke Road, Concord, NH 03301

Phone

(603) 224-1961

Fax

603-224-1430

Internet

www.vishay.com

Major Vishay Brands

Dale Draloric Foil Resistors Measurements Group Roederstein Sfernice Sprague Thin Film Vitramon

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 595D157X9016R2T | KONDENSATOR TANTAL SMD 150UF 16V |

| 595D225X9010T2T | KONDENSATOR TANTAL SMD 2.2UF 10V |

| 595D225X9020A2T | KONDENSATOR TANTAL SMD 2.2UF 20V |

| 595D225X9035B2T | KONDENSATOR TANTAL SMD 2.2UF 35V |

| 595D226X9020C2T | KONDENSATOR TANTAL SMD 22UF 20V |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 595D156X96R3A2T | 制造商:Vishay Roederstein 功能描述:CAPACITOR CASE A 15UF 6.3V |

| 595D156X96R3A2W | 功能描述:CAP TANT 15UF 6.3V 10% 1507 RoHS:是 類別:電容器 >> 鉭 系列:TANTAMOUNT® 595D 標(biāo)準(zhǔn)包裝:1,000 系列:TANTAMOUNT® 695D 電容:3.3µF 電壓 - 額定:50V 容差:±20% ESR(等效串聯(lián)電阻):3.2 歐姆 類型:保形涂層 工作溫度:-55°C ~ 125°C 安裝類型:表面貼裝 封裝/外殼:2414(6034 公制) 尺寸/尺寸:0.236" L x 0.135" W(6.00mm x 3.43mm) 高度 - 座高(最大):0.085"(2.16mm) 引線間隔:- 制造商尺寸代碼:F 特點(diǎn):通用 包裝:帶卷 (TR) 壽命@溫度:- |

| 595D157X_004B2T | 制造商:VISHAY 制造商全稱:Vishay Siliconix 功能描述:Solid Tantalum Chip Capacitors TANTAMOUNT? Conformal Coated, Maximum CV |

| 595D157X_004C2T | 制造商:VISHAY 制造商全稱:Vishay Siliconix 功能描述:Solid Tantalum Chip Capacitors TANTAMOUNT? Conformal Coated, Maximum CV |

| 595D157X_010C2T | 制造商:VISHAY 制造商全稱:Vishay Siliconix 功能描述:Solid Tantalum Chip Capacitors TANTAMOUNT? Conformal Coated, Maximum CV |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。