- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄357314 > 48D5.800WD 2-OUTPUT 10 W DC-DC REG PWR SUPPLY MODULE PDF資料下載

參數(shù)資料

| 型號: | 48D5.800WD |

| 元件分類: | 電源模塊 |

| 英文描述: | 2-OUTPUT 10 W DC-DC REG PWR SUPPLY MODULE |

| 文件頁數(shù): | 5/6頁 |

| 文件大小: | 102K |

| 代理商: | 48D5.800WD |

10 Watt WD Dual Series DC/DC Converters

2401 Stanwell Drive Concord, California 94520 Ph: 925/687-4411 or 800/542-3355 Fax: 925/687-3333 www.calex.com Email: sales@calex.com

5

3/2001

Grounding

The input and output sections are fully floating from each

other. They may be operated fully floating or with a common

ground. If the input and output sections are connected either

directly at the converter or at some remote location from the

converter it is suggested that a 1 to 10μF, 0.5 to 5 ohm ESR

capacitor bypass be used directly at the converters output

pins. These capacitors prevent any common mode switching

currents from showing up at the converters output as normal

mode output noise. See

“

Applying the Output

”

for more

information on selecting output capacitors.

Also see the CALEX application note

“

Dealing With

Common Mode Noise

”

for more information on using common

grounds.

Case Grounding

The copper case serves not only as a heat sink but also as a

EMI shield. The 0.017 inch thick case provides >20 dB of

absorption loss to both electric and magnetic fields at 120

kHz, while at the same time providing 20 to 40 % better heat

sinking over competitive thin steel, aluminum or plastic designs.

The case shield is tied to the CMN output pin. This

connection is shown on the block diagram. The case is

floating from the input sections. The input is coupled to the

outputs only by the low 375 pF of isolation capacitance. This

low I/O capacitance insures that any AC common mode noise

on the inputs is not coupled to your output circuits.

Compare this isolation to the more usual 1000 - 2000 pF

found on competitive designs and you will see that CALEX

provides the very best DC and AC isolation available. After all,

you are buying an isolated DC/DC to cut ground loops. Don

’

t

let the isolation capacitance add them back in.

Temperature Derating

The WD Dual series can operate up to 85

°

C case temperature

without derating. Case temperature may be roughly calculated

from ambient by knowing that the case temperature rise is

approximately 16

°

C per package watt dissipated.

For example: If a WD Dual converter is delivering 8 Watts

with a 48 volt input, at what ambient could it expect to run with

no moving air and no extra heatsinking

Efficiency of the converter is approximately 80% at 8 watts

of output power, this leads to an input power of about 10

Watts. The case temperature rise would be 10 - 8 Watts or 2

Watts x 16 = 32

°

C. This number is subtracted from the

maximum case temperature of 85

°

C to get: 53

°

C.

This example calculation is for a WD Dual without any extra

heat sinking or appreciable air flow. Both of these factors can

greatly effect the maximum ambient temperature (see below).

Exact efficiency depends on input line and load conditions,

check the efficiency curves for exact information.

This is a rough approximation to the maximum ambient

temperature. Because of the difficulty of defining ambient

temperature and the possibility that the loads dissipation may

actually increase the local ambient temperature significantly,

these calculations should be verified by actual measurement

before committing to a production design.

Applying The Output

Figure 1 shows typical output connections for the WD Dual. In

most applications no external output capacitance will be

necessary. Only your normal 1 to 10μF tantalum and 0.001 to

0.1μF ceramic bypass capacitors sprinkled around your circuit

as needed locally are required. Do not add extra output

capacitance and cost to your circuit

“

Just Because

”

.

If you feel you must add external output capacitance, do

not use the lowest ESR, biggest value capacitor that you can

find! This can only lead to reduced system performance or

oscillation. See our application note

“

Understanding Output

Impedance For Optimum Decoupling

”

for more information

and by all means use our low noise circuit provided.

Single Ended 10, 24 or 30 V Outputs

The dual outputs may also be used in a single ended mode as

shown in figure 1 to get 10, 24 or 30 volts of output at the full

rated power levels. To use the single ended mode just

connect your load to the + and - Output pins and leave the

CMN pin floating.

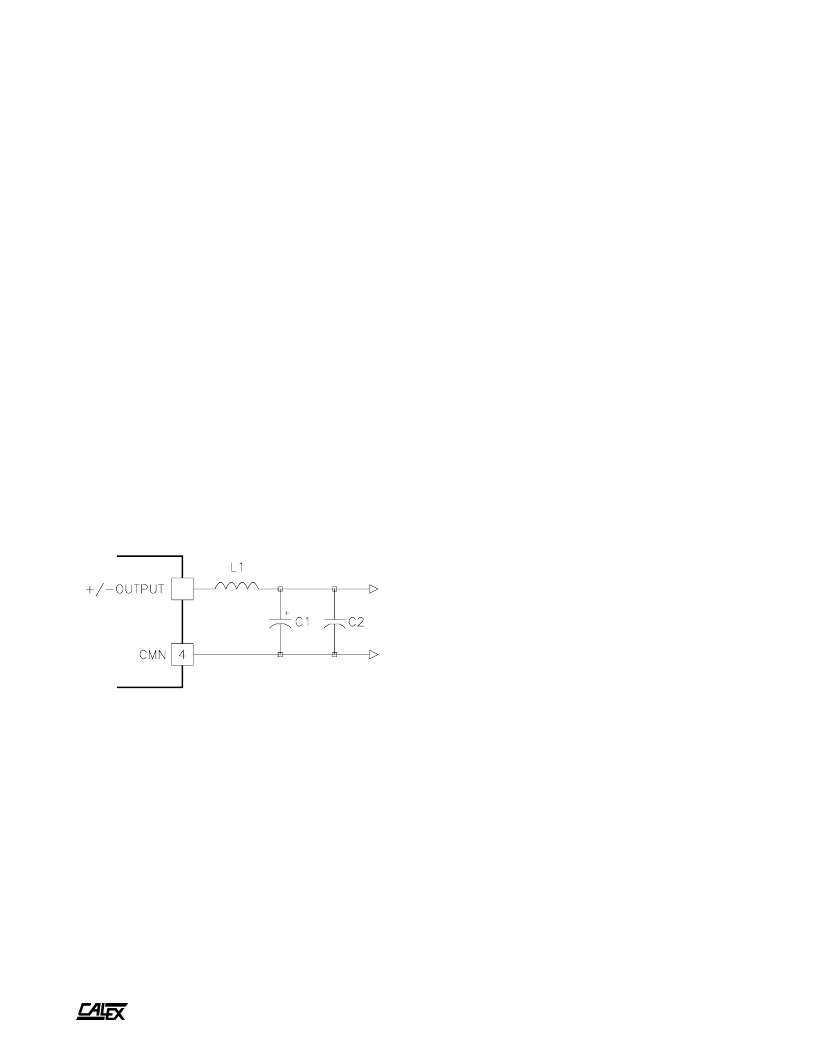

Ultra Low Noise Output Circuit

The circuit shown in figure 3 can be used to reduce the output

noise to below 10 mV p-p over a 20 MHz bandwidth. Size

inductor L1 appropriately for the maximum expected load

current. All of the ground connections must be as short as

possible back to the CMN pin. The filter should be placed as

close to the WD Dual as possible, even if your load is at some

distance from the converter.

Figure 3.

This circuit can reduce the output noise to below 10 mV p-p over a

20 MHz bandwidth. Size inductor L1 appropriately for the maximum

expected load current. The filter should be constructed as close as

possible to the converter and all of the ground connections must be

as short as possible back to the CMN pin.

Operation With Very Light Loads

Dynamic response and cross regulation of the WD Dual will

degrade when the unit is operated with less than about 25%

of full rated power. If this is a problem the most lightly loaded

output may be

“

Pre-Loaded

”

with a resistor to common as

needed. The exact amount of preloading required is dependent

on your system requirements, so some experimentation is

necessary to arrive at the optimum value.

L1 = 20 μH

C1= 22 μF / 20 V, Tantalum

C2= 0.01 μF / 100 V, Ceramic

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| 48IML10-12-12-0C | 2-OUTPUT 10.8 W DC-DC REG PWR SUPPLY MODULE |

| 48IMP3-1212-7S | 2-OUTPUT 3 W DC-DC REG PWR SUPPLY MODULE |

| 48S12.850TC | 1-OUTPUT 10 W DC-DC REG PWR SUPPLY MODULE |

| 48S15.3XT-HS | 1-OUTPUT 45 W DC-DC REG PWR SUPPLY MODULE |

| 48S5.8XT-HS-1 | 1-OUTPUT 45 W DC-DC REG PWR SUPPLY MODULE |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| 48DA/ARHDFA | 制造商:Olympic Controls Corporation 功能描述: |

| 48DA18AA8 | 制造商:Siemens 功能描述: |

| 48DC107148 | 制造商:Siemens 功能描述: |

| 48DC107640 | 制造商:Siemens 功能描述: |

| 48DC18A2 | 制造商:Siemens 功能描述: |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。