- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄382789 > μPD789012 (NEC Corp.) 8 Bit Single Chip Microcontrollers(8位單片微控制器) PDF資料下載

參數(shù)資料

| 型號: | μPD789012 |

| 廠商: | NEC Corp. |

| 英文描述: | 8 Bit Single Chip Microcontrollers(8位單片微控制器) |

| 中文描述: | 8位單片機微控制器(8位單片微控制器) |

| 文件頁數(shù): | 39/44頁 |

| 文件大小: | 271K |

| 代理商: | ΜPD789012 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁當前第39頁第40頁第41頁第42頁第43頁第44頁

μ

PD789011, 789012

39

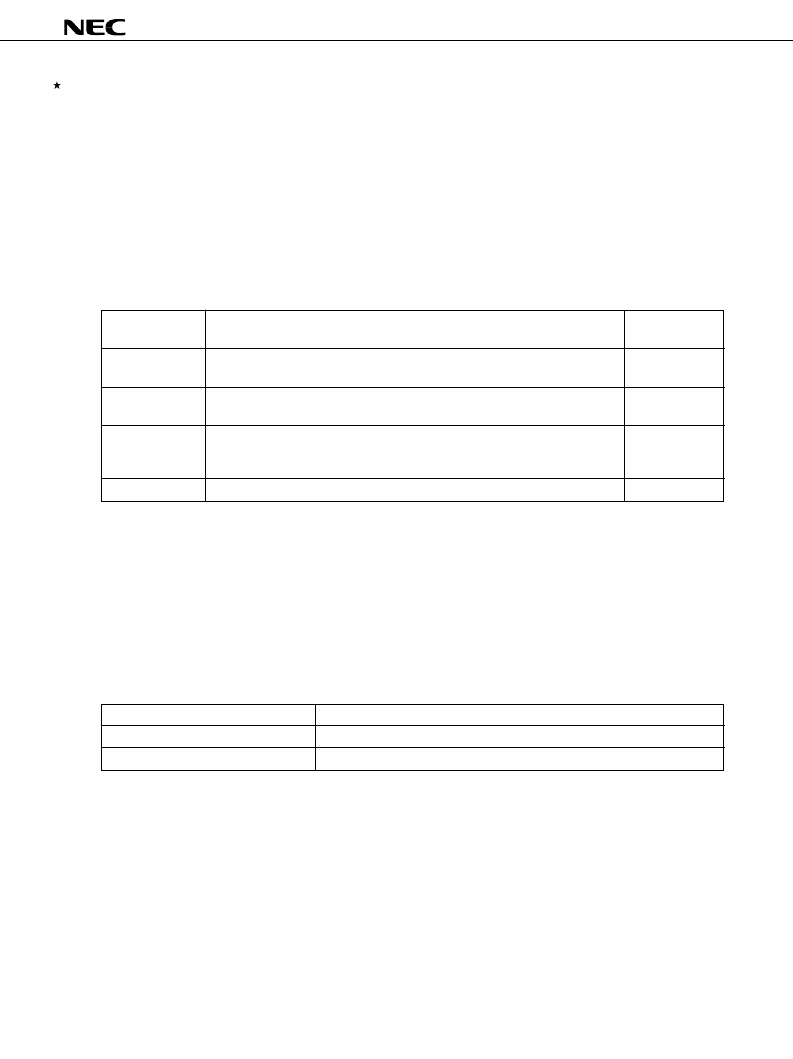

12. RECOMMENDED SOLDERING CONDITIONS

The

μ

PD789011 and 789012 should be soldered and mounted under the conditions recommended in the table

below.

For detail of recommended soldering conditions, refer to the information document

Semiconductor Device

Mounting Technology Manual

(C10535E).

For soldering methods and conditions other than those recommended below, contact an NEC sales representative.

Table 12-1. Soldering Conditions for Surface-mount Devices

μ

PD789011GT-

×××

: 28-pin Plastic SOP (375 mil)

μ

PD789012GT-

×××

: 28-pin Plastic SOP (375 mil)

Recommended

Condition Code

Soldering Method

Soldering Conditions

Infrared reflow

Package peak temperature: 235

°

C, Duration: 30 seconds max. (at 210

°

C or above)

Number of times: two times max.

VPS

Package peak temperature: 215

°

C, Duration: 40 seconds max. (at 200

°

C or above)

Number of times: two times max.

Wave soldering

Soldering bath temperature: 260

°

C max., Duration: 10 seconds max., Number of

times: Once

Preheating temperature: 120

°

C max.(Package surface temperature)

Partial heating

Pin temperature: 300

°

C max., Duration: 3 seconds max. (per device side)

Note

The storage conditions are 25

°

C and 65% RH for the number of storage days after opening the seal of the

dry pack.

Caution

Using more than one soldering method should be avoided. (except in the case of partial heating)

Table 12-2. Soldering Conditions for Through-hole Devices

μ

PD789011CT-

×××

: 28-pin Plastic Shrink DIP (400 mil)

μ

PD789012CT-

×××

: 28-pin Plastic Shrink DIP (400 mil)

Soldering Method

Soldering Conditions

Wave soldering (pin only)

Solder bath temperature: 260

°

C max., Duration: 10 seconds max.

Partial heating

Pin temperature: 300

°

C max., Duration: 3 seconds max.(per pin)

Caution

Wave soldering is only for the lead part in order that jet solder cannot contact with the chip

directly.

IR35-00-2

VP15-00-2

WS60-00-1

—

相關PDF資料 |

PDF描述 |

|---|---|

| μPD789024 | 8 Bit Single Chip Microcontrollers(8位單片微控制器) |

| μPD789025 | 8 Bit Single Chip Microcontrollers(8位單片微控制器) |

| μPD789026 | 8 Bit Single Chip Microcontrollers(8位單片微控制器) |

| μPD789022 | 8 Bit Single Chip Microcontrollers |

| μPD789104CT | 8 Bit Gerneral-Purpose Microcontrollers(8 位通用微控制器) |

相關代理商/技術參數(shù) |

參數(shù)描述 |

|---|---|

| PD78F0134 | 制造商:NEC 制造商全稱:NEC 功能描述:8-Bit Single-Chip Microcontrollers |

| PD78F0134(A) | 制造商:NEC 制造商全稱:NEC 功能描述:8-Bit Single-Chip Microcontrollers |

| PD78F0134(A1) | 制造商:NEC 制造商全稱:NEC 功能描述:8-Bit Single-Chip Microcontrollers |

| PD78F0134A | 制造商:NEC 制造商全稱:NEC 功能描述:8-Bit Single-Chip Microcontrollers |

| PD78F0134A1 | 制造商:NEC 制造商全稱:NEC 功能描述:8-Bit Single-Chip Microcontrollers |

發(fā)布緊急采購,3分鐘左右您將得到回復。