- 您現(xiàn)在的位置:買(mǎi)賣(mài)IC網(wǎng) > PDF目錄374939 > STF202-22TC (Semtech Corporation) USB Upstream Port Filter & TVS For EMI Filtering and ESD Protection PDF資料下載

參數(shù)資料

| 型號(hào): | STF202-22TC |

| 廠商: | Semtech Corporation |

| 英文描述: | USB Upstream Port Filter & TVS For EMI Filtering and ESD Protection |

| 中文描述: | 上游的USB端口過(guò)濾 |

| 文件頁(yè)數(shù): | 4/6頁(yè) |

| 文件大小: | 164K |

| 代理商: | STF202-22TC |

2000 SEMTECH CORP.

652 MITCHELL ROAD NEWBURY PARK CA 91320

Objective - March 03, 2000

USB Upstream Port Filter & TVS

For EMI Filtering and ESD Protection

STF202-22

&

STF202-30

APPLICATIONS INFORMATION

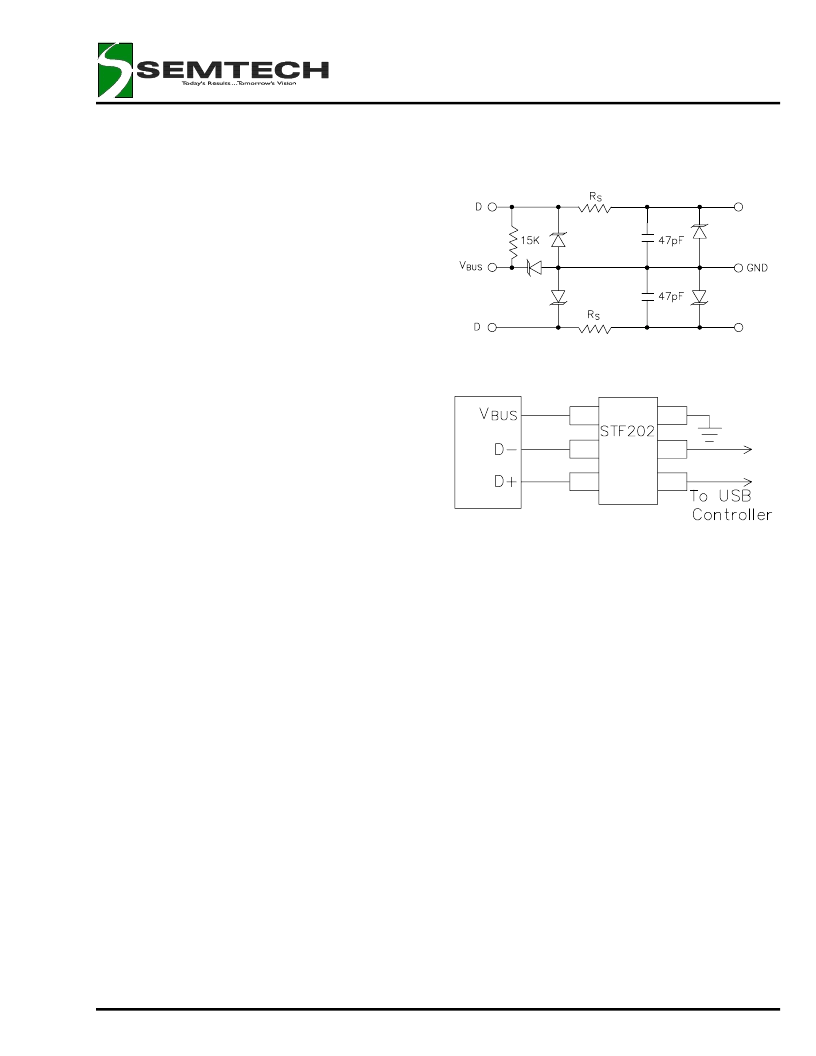

Figure 1 - STF202 Circuit Diagram

Device Connection

The STF202 is designed to provide termination, EMI

filtering and ESD protection for two USB I/O lines. The

equivalent circuit diagram is shown in Figure 1. The

device is connected as follows:

1. Full-Speed Devices:

For full-speed devices the

pull-up resistor is connected to the D+ line. Pin 1

is connected to the voltage supply line (V

BUS

). The

input of the D+ line is routed into pin 3 and out of

pin 4. The input of the D- line is connected at pin 2

and the output at pin 5. Pin 6 is connected to

ground.

Low-Speed Devices:

For low speed devices the

pull-up resistor is connected to the D- line. Pins 1

is connected to the voltage supply line (V

BUS

). The

input of the D- line is connected at pin 3 with the

output taken at pin 4. The input of the D+ line is

connected to pin 2 and the output is at pin 5. Pin 6

is connected to ground.

USB Port Design Considerations

The Universal Serial Bus (USB) specification requires

termination and filtering components for proper

operation. In addition, an open USB socket is

vulnerable to hazardous ESD discharges in excess of

15kV. These discharges can may occur on the data

lines or the voltage bus. The STF202 is an easily

implemented solution designed to meet the termination

& EMI filter requirements of the USB specification

revision 1.1. It also provides ESD protection to IEC

61000-4-2, level 4.

A simplified USB port is shown in Figure 3. USB line

termination is achieved with series resistors on both the

D+ and D- lines. These resistors preserve signal

integrity by matching the cable impedance to that of the

differential driver. 15k

pull-down resistors are used to

identify a downstream port while an upstream port is

identified with a 1.5K

pull up resistor on either the D+

(full speed devices) or the D- (low speed devices) data

line. Capacitors are used to bypass high frequency

energy to ground and for edge rate control of the USB

signals. TVS diodes are added for ESD protection of

both (D+ & D-) data lines and the voltage bus (V

BUS

). A

power distribution switch and voltage regulator provide

the power management functions of the port.

Semtech provides a complete solution to simplify USB

port design (Figure 4). The STF201 & STF202

Figure 2 - STF202 Connection Diagram

(Full Speed Devices)

1

2

3

4

5

6

integrate all of the components necessary for line

termination, bidirectional EMI filtering, and ESD

protection on downstream (STF201) or upstream

(STF202) ports. The SC5826 is a dual port power

switch that provides individual or ganged port

switching, fault reporting, and inrush current limiting as

required by the USB specification. The SC5205 ULDO

provides a stable voltage to the USB controller.

Board Placement & Layout Guidelines.

Designing a USB hub to meet EMI & ESD immunity

requirements requires a combination of optimum

component placement, trace routing, and good circuit

design practices. Some general guidelines are given

below:

Avoid running D+ & D- signal line traces near high

speed clock lines or similar signal lines.

Avoid running critical signal lines near board

edges.

Locate the USB controller chip near the USB

connectors.

Place the STF202 near the USB connector to

restrict transient coupling.

Minimize the path length between the USB

connector and the STF202

.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| STF202-30 | USB Upstream Port Filter & TVS For EMI Filtering and ESD Protection |

| STF202-30TC | USB Upstream Port Filter & TVS For EMI Filtering and ESD Protection |

| STF701 | T-Filter with TVS Diode Array For EMI Filtering and ESD Protection |

| STF701TC | T-Filter with TVS Diode Array For EMI Filtering and ESD Protection |

| STF701TG | T-Filter with TVS Diode Array For EMI Filtering and ESD Protection |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| STF202-30 | 制造商:SEMTECH 制造商全稱:Semtech Corporation 功能描述:USB Upstream Port Filter & TVS For EMI Filtering and ESD Protection |

| STF202-30.TC | 制造商:Semtech Corporation 功能描述:EMI Filter Gull Wing SMD 制造商:Semtech Corporation 功能描述:1 FUNCTIONS, 6 V, DATA LINE FILTER |

| STF202-30.TCT | 制造商:Semtech Corporation 功能描述:EMI Filter Gull Wing SMD T/R 制造商:Semtech Corporation 功能描述:USB UP-STREAM PORT FILTER & TVS / LEAD-F |

| STF202-30TC | 制造商:SEMTECH 制造商全稱:Semtech Corporation 功能描述:USB Upstream Port Filter & TVS For EMI Filtering and ESD Protection |

| STF203-15 | 制造商:SEMTECH 制造商全稱:Semtech Corporation 功能描述:USB Upstream Port Filter and TVS |

發(fā)布緊急采購(gòu),3分鐘左右您將得到回復(fù)。